FH Görsel Denetim Sistemi

Daha yüksek makine çalışma hızı, her uygulamaya uygun kamera

Bu seri, Akıllı Kameranın avantajlarını ve güçlü bir Görsel Denetim Sistemini tek bir platformda bir araya getirir. Akıllı kamera kullanılarak elde edilen benzersiz görüntü netliği, basit kurulum, hızlı montaj ve gelişmiş optik performans sağlar.

- Yüksek performanslı komponentler, en zorlu gereksinimleri karşılayarak olağanüstü bir performans sunar

- Akıllı algoritmalar ve görsel denetim araçları, hangi hızda olursa olsun tüm uygulamaları sağlam ve güvenilir kılar

- Modern kamera serisi, her uygulama için en uygun donanımı seçmenize olanak sağlar. Böylece en iyi fiyata en iyi performansı elde edersiniz

- Yapay zeka, insan duyarlılığın ve deneyimin yeniden üretir

- Esnek otomasyon için yazılımla kolay entegrasyon

- Gerçek Renk İşleme (16 milyon renk)*

- EtherNet/IP ve TCP/IP haberleşme*

Yardıma mı ihtiyacınız var?

Yardımcı olmak için buradayız! Bize ulaşın, uzmanlarımız işletmeniz için en iyi çözümü bulmanıza yardımcı olsun.

İletişime geçin FH Görsel Denetim Sistemi

Teşekkür ederiz. Talebiniz konusunda en kısa sürede bilgilendirileceksiniz.

Teknik zorluklar yaşamaktayız. Form gönderme işleminiz başarılı olmadı. Lütfen özürlerimizi kabul edin ve daha sonra tekrar deneyin. Detaylar: [details]

DownloadIçin teklif FH Görsel Denetim Sistemi

Bu form ile seçtiğiniz ürün için bir teklif isteyebilirsiniz. * ile işaretli bölümleri doldurmak zorunludur. Kişisel bilgileriniz gizli kalacaktır.

Talebiniz için teşekkür ederiz. En kısa zamanda size bilgi verilecektir.

Teknik zorluklar yaşamaktayız. Form gönderme işleminiz başarılı olmadı. Lütfen özürlerimizi kabul edin ve daha sonra tekrar deneyin. Detaylar: [details]

DownloadÖzellikler

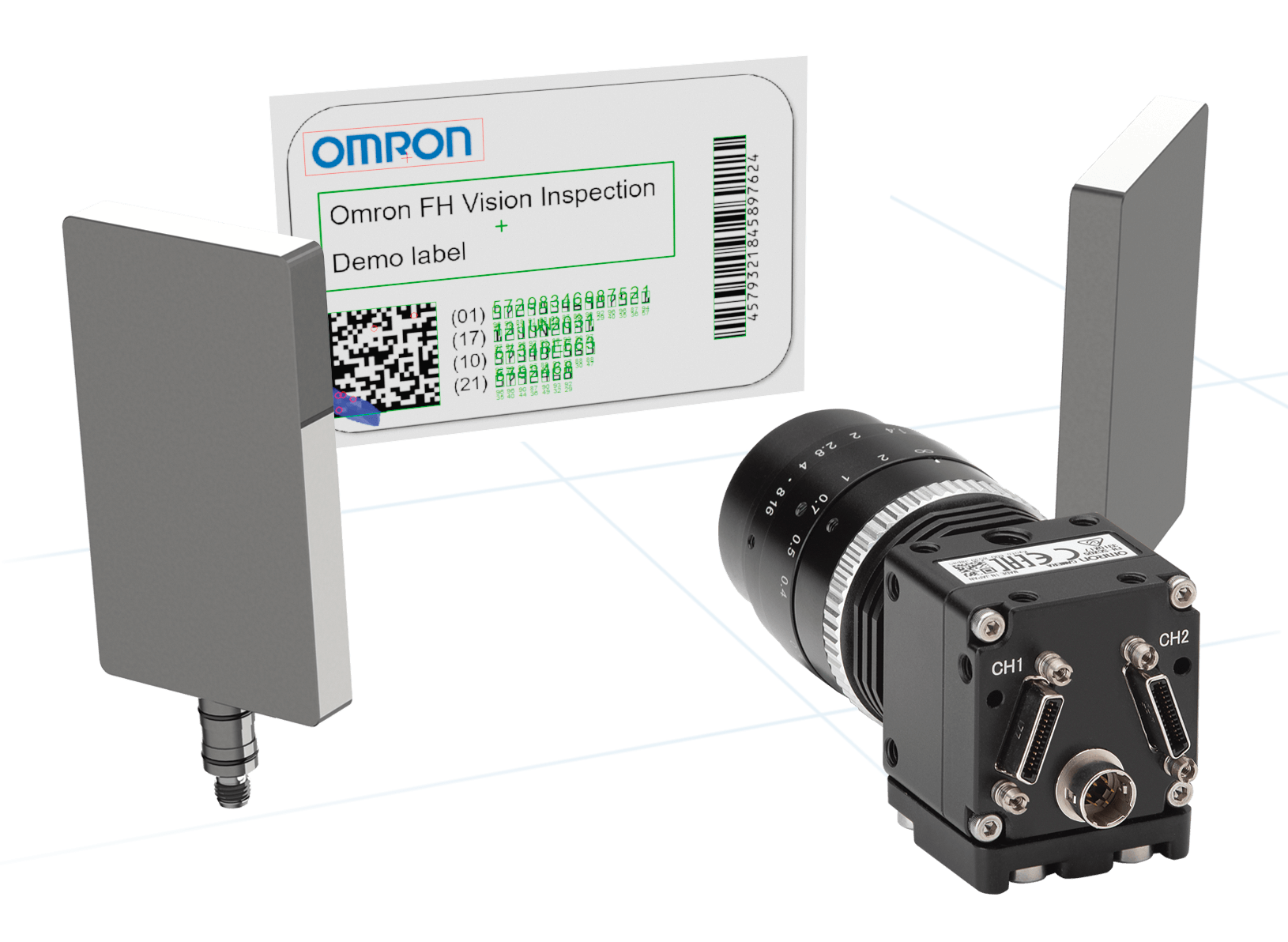

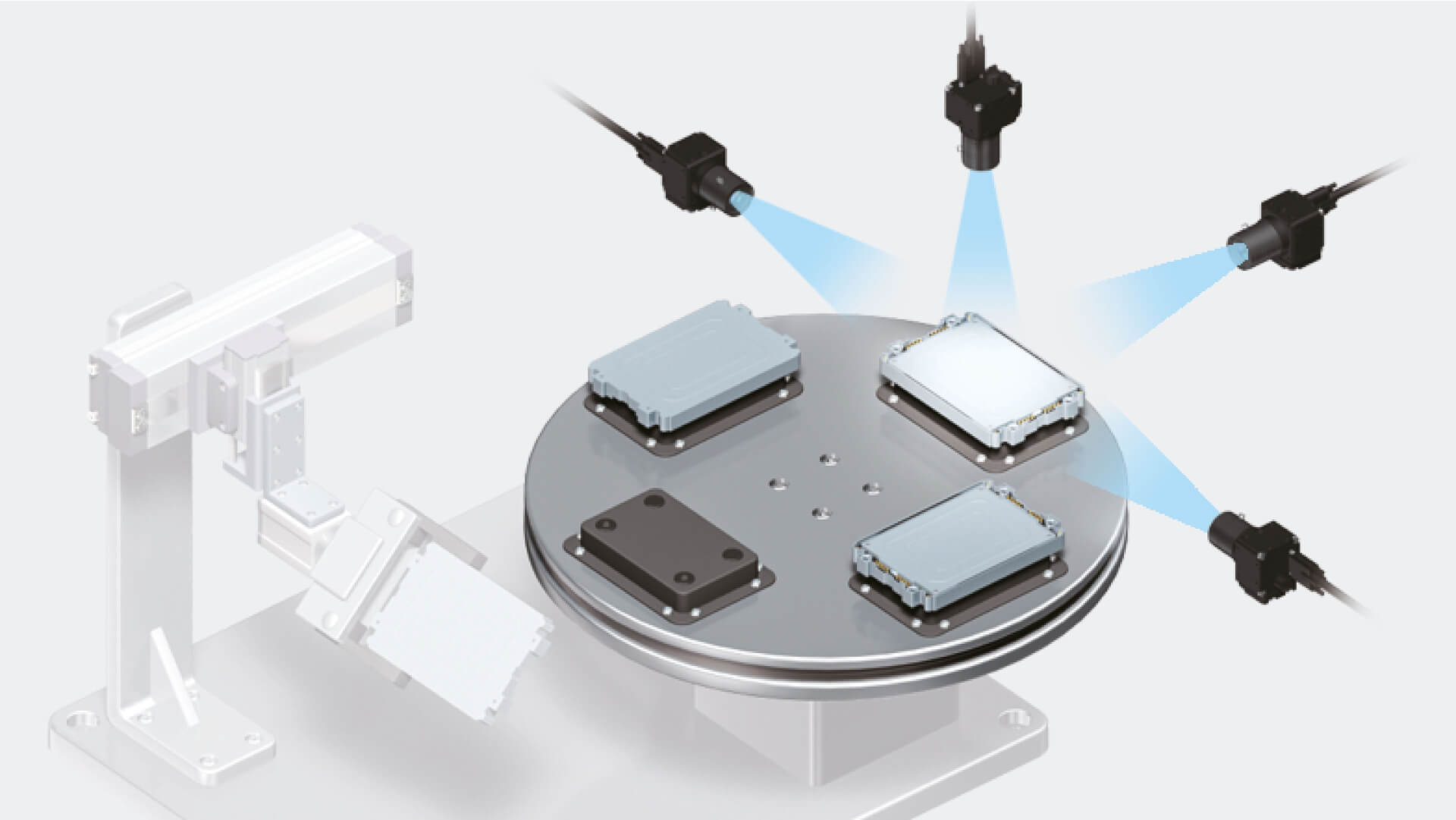

Eksiksiz Yüksek Hızlı/Yüksek Çözünürlüklü kamera serisi

FH Kameraları her türlü nesne denetimi, konum/yön, kod okuma ve ölçüm uygulamalarında kullanılmak üzere tasarlanmıştır. Bu kompakt kamera ve kontrolör sistemi neredeyse her makine veya robota kolaylıkla entegre edilebilir. Size daha fazla verimlilik, daha az maliyet ve daha fazlasını sunmak üzere sistem, benzersiz bir şekilde daha hızlı ve daha kesin iş hacmi sağlama kapasitesine sahiptir.

SWIR ve Polarize Kameralar ile Genişletilmiş Algılama

OMRON, kamera portföyünü genişleterek görüntü algılama özelliklerini önemli ölçüde geliştirmiştir. Artık iki SWIR kamera çözünürlüğü ve iki polarize çözünürlüklü kamera sunuyoruz. Bu yeni ürünler FH serisinin algılama aralığını ve çok yönlülüğünü büyük ölçüde artırır

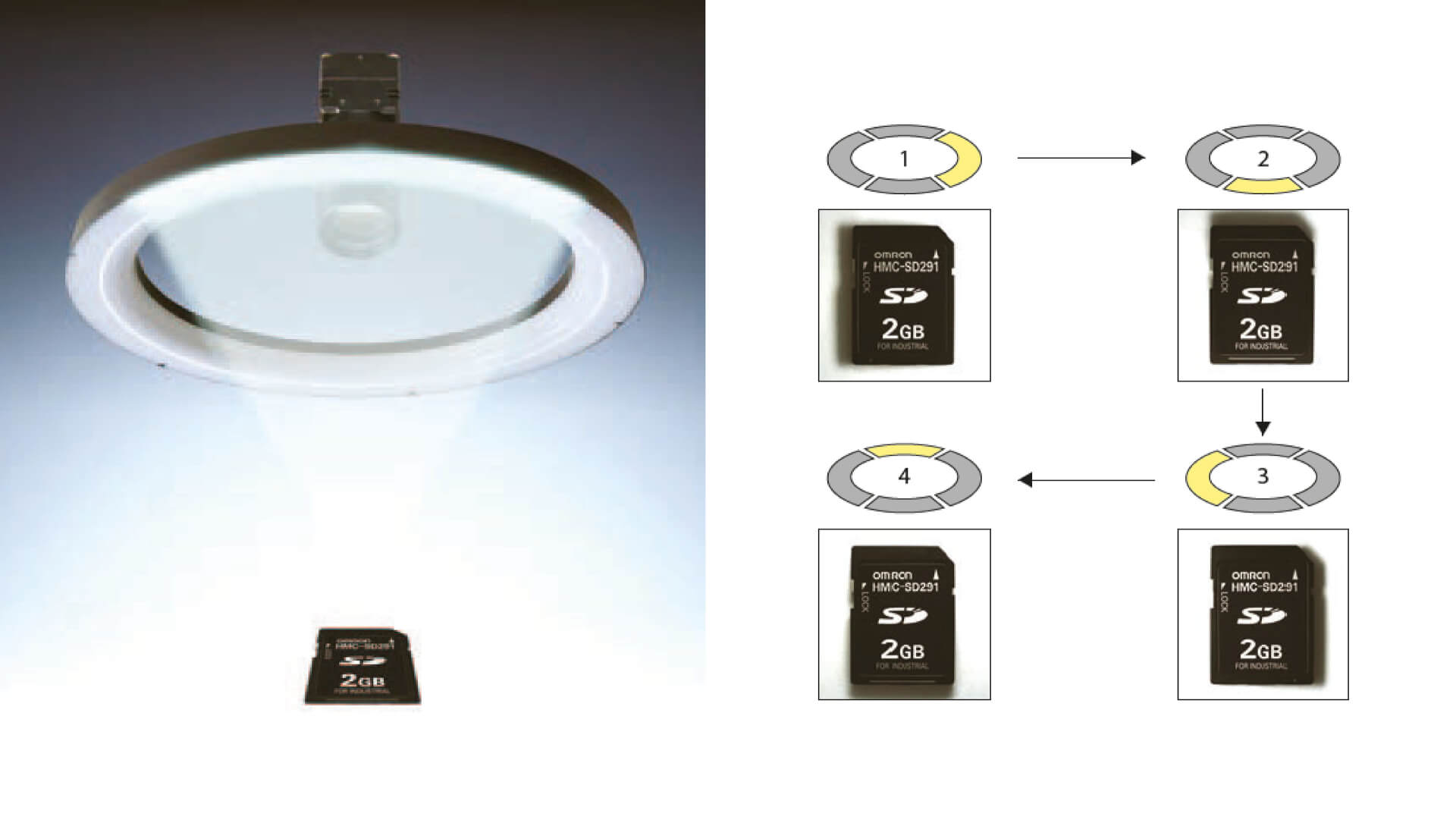

Gelişmiş Fotometrik Stereo Görüntüleme

FH fotometrik Stereo Işık, göçükleri ve yüzey hasarlarını yüksek doğrulukla algılamak üzere 20,4 MP'ye kadar standart veya yüksek çözünürlüklü kameralarla kullanılabilir. Dört ışık sırayla yanar ve parlaklık değişimleri analiz edilir. Parlaklık farklılıkları az olan basılı karakterler, farklı aydınlatma yönlerinde bile doku olarak ve büyük parlaklık farklarına sahip bir göçük şekil olarak çıkarılır

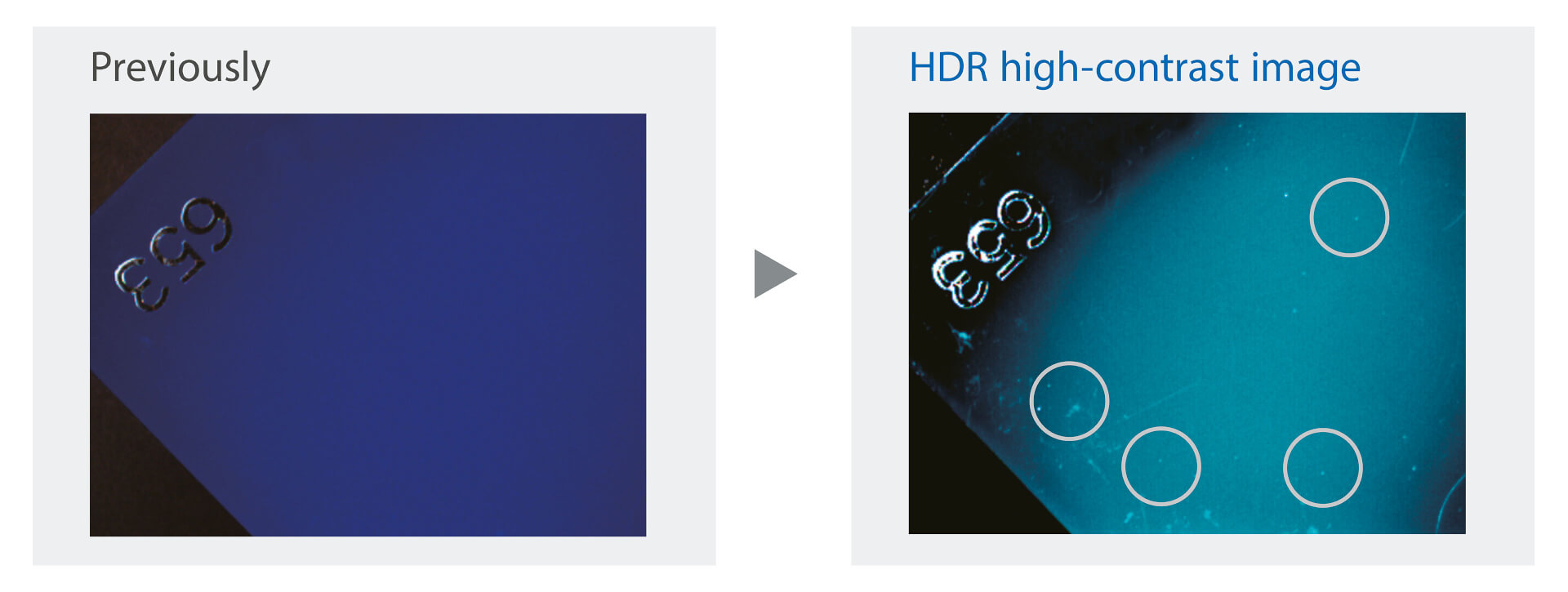

HDR Görüntüleme

HDR, değişken ortam koşullarında optimize edilmiş görüntüler oluşturmaya yardımcı olur. Görüntü üzerinde çekim yapmak için optimum alanı belirledikten sonra FH Serisi, görüntüleri yakalayıp birleştirirken enstantane hızını otomatik olarak ayarlar.

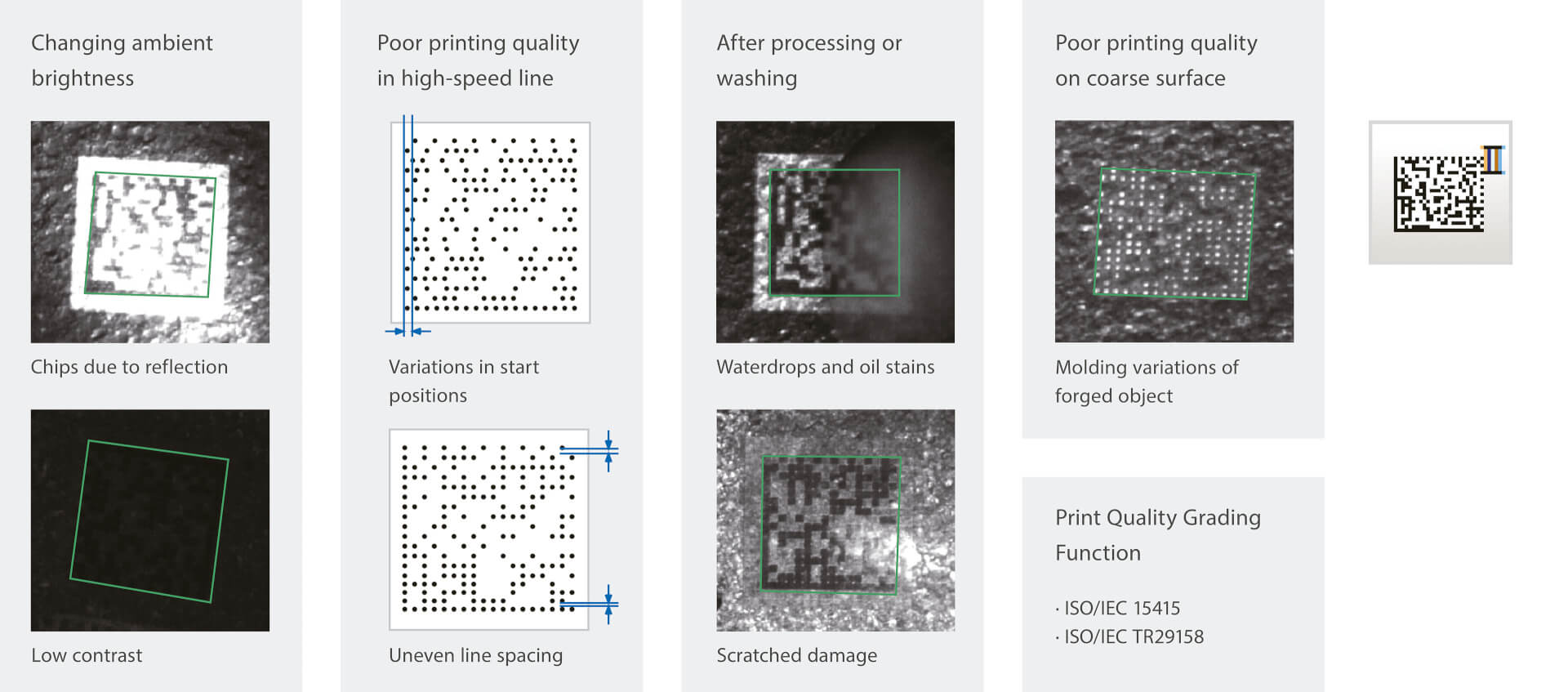

Kapsamlı Kural Tabanlı Görsel Denetim Araçları

OMRON'un FH kural tabanlı görsel denetim araçları; kalite kontrol, denetim ve süreç optimizasyonu için en son teknoloji çözümleri sunarak modern endüstriyel otomasyona öncülük eder. Gelişmiş algoritmalar ve hassas görüntüleme teknolojisinden yararlanan bu araçlar, karmaşık görevleri olağanüstü doğruluk ve güvenilirlikle gerçekleştirir. OMRON görsel denetim araçları kullanıcı dostu olacak şekilde tasarlanmıştır. Mevcut sistemlerle sorunsuz entegrasyon sağlar ve minimum kurulum süresi gerektirir.

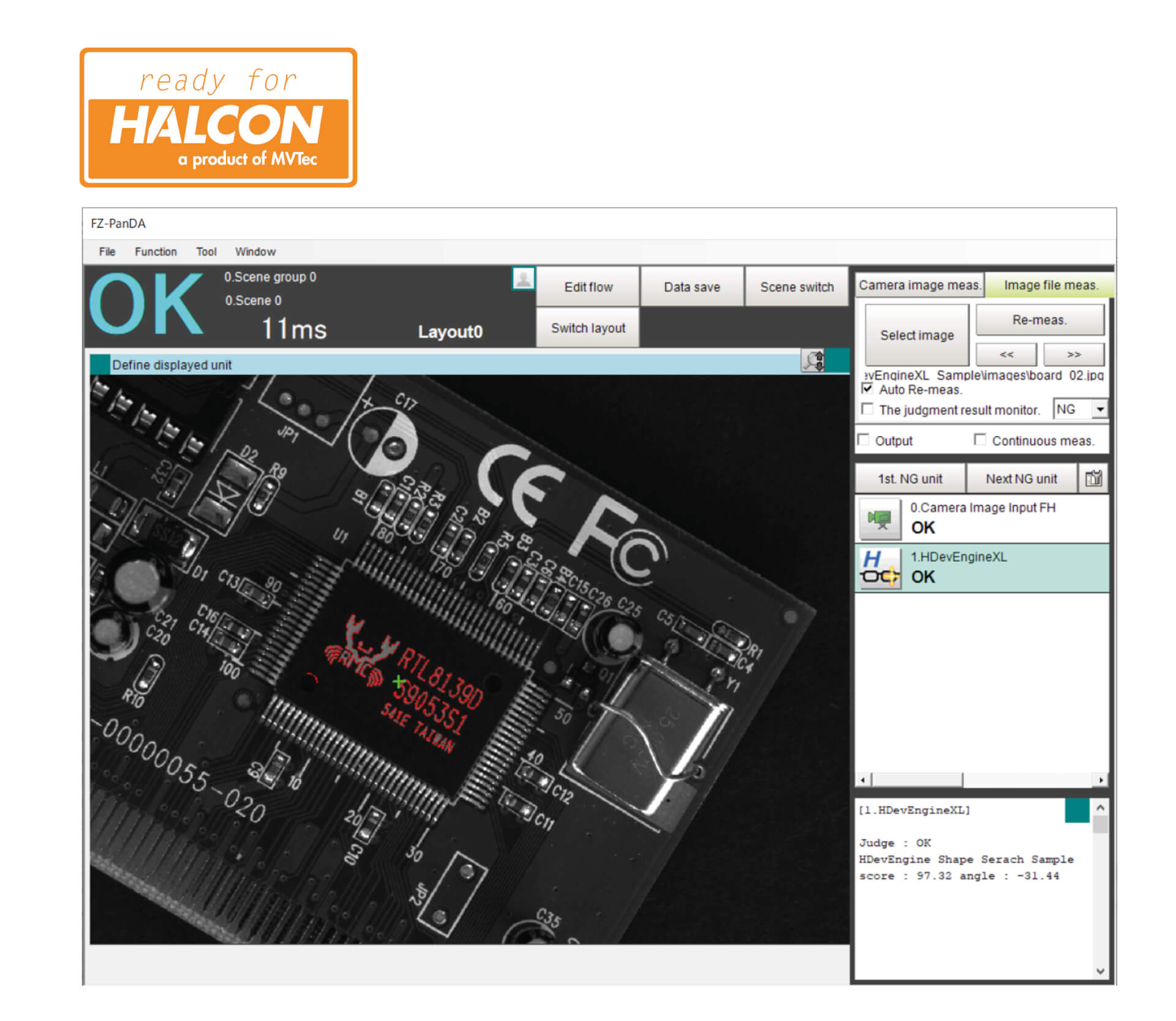

Açık FH

OMRON'un tescilli Görsel Denetim algoritmalarına ek olarak FH Görsel Denetim kontrolörü, MVTec'in Halcon HDevelop yazılımı kullanılarak geliştirilen Görsel Denetim algoritmalarıyla da uyumludur. Bu esneklik, üreticilerin özel uygulama gereksinimleri için en iyi algoritmik yaklaşımı seçmelerine olanak tanıyarak görsel denetim çözümlerinde optimum performans ve verimlilik sağlar

Esnek Uç Yapay Zekası

Özenle seçilmiş Intel CPU teklifiyle güçlendirilen ve OpenVINO araç kitiyle geliştirilen FH Görsel Denetim kontrolörü ile yapay zekaya dayalı otomasyonun tüm potansiyelini ortaya çıkarın. Bu güçlü sinerji, gelişmiş yapay zeka modellerini FH Görüntü kontrolöründe doğrudan kullanmanıza olanak tanıyarak olağanüstü gerçek zamanlı görüntü işleme ve analizi sağlar. OpenVINO araç kiti, performansı optimize ederek derin öğrenme çıkarımlarının minimum gecikmeyle sorunsuz bir şekilde yürütülmesini mümkün kılar. Bu da daha hızlı ve daha doğru karar verme, daha yüksek operasyonel verimlilik ve üstün kalite kontrolü anlamına gelir. Çığır açan OpenVINO araç kiti aracılığıyla en son teknoloji yapay zekayı Intel'in gelişmiş bilgi işlem özellikleriyle bir araya getiren OMRON FH Görsel Denetim kontrolörü ile otomasyon süreçlerinizi geliştirin.

Yapay Zeka ile Kusur Algılama

Gelişmiş makine öğrenimi algoritmalarından yararlanan FH kontrolör, üreticilerin çeşitli üretim süreçlerinde kusurları belirleme ve kategorilere ayırma konusunda benzersiz bir doğruluk ve verimlilik elde etmesini sağlar. Anormalliklerin tespiti, sınıflandırılması ve segmentasyon görevleri dahil olmak üzere yapay zeka ile çalışan kusur denetimini destekler.

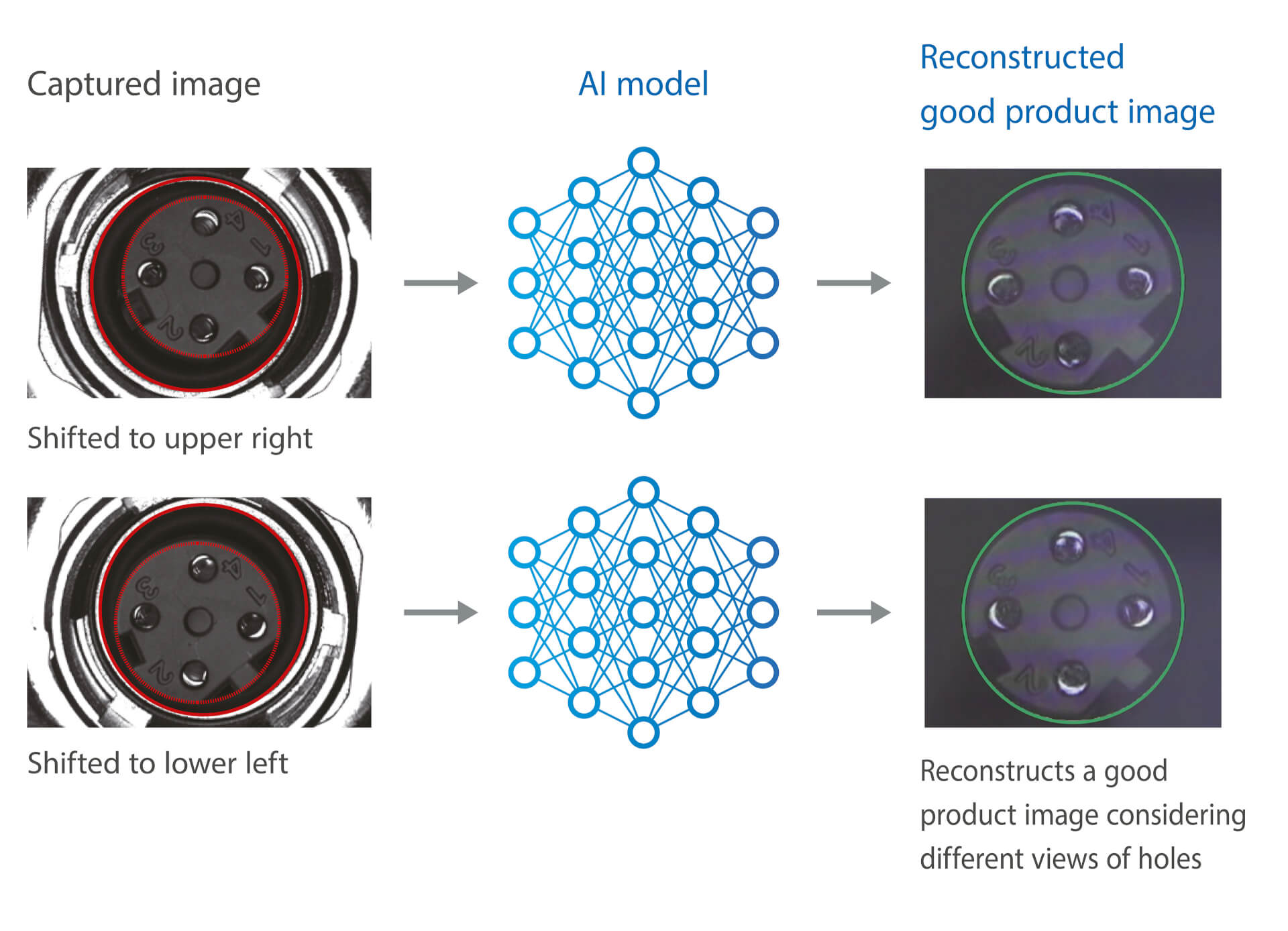

Yapay Zeka ile Hassas Eşleştirme

Yapay zeka ile hassas eşleştirme, iyi ürünlerde bulunmayan bir özelliği kusur olarak tanımlar. Yapay zeka, varyasyonlara sahip iyi ürünlerin görüntülerini öğrenir ve bir Yapay Zeka Modeli oluşturur. Her denetim yapıldığında yapay zeka, iyi bir ürün olduğu varsayılan modeli yeniden yapılandırır. Yapay zeka, yeniden oluşturulan iyi ürün görüntüsü ile yakalanan görüntü arasındaki farkı çıkararak Kusuru tespit eder ve aşırı algılamayı azaltır.

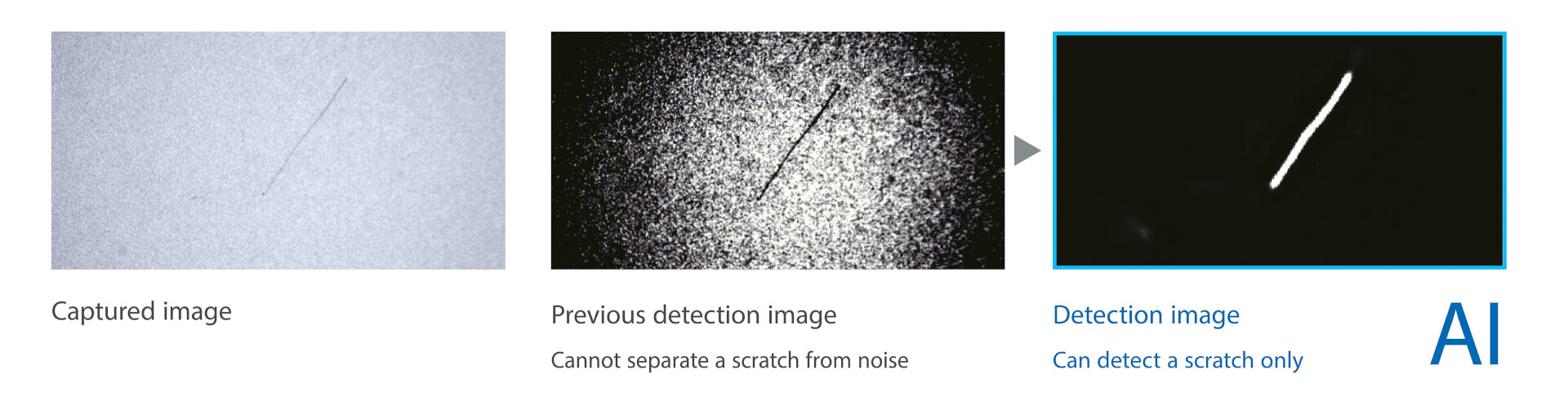

Yapay Zeka ile Çizik Algılama

FH Görsel Denetim Sisteminin en yeni özellikleri, uzman denetimcilerin herhangi bir ürün arka planındaki bir kusuru tespit etmek için kullandığı tekniği yeniden üreten yapay zeka tabanlı bir görüntü filtresi içerir. Bir zamanlar yakalaması zor olan çizikler ve lekeler artık numuneler veya ayarlama kullanılmadan dahi tespit edilebilir

Uygulamalar

21 CFR Bölüm 11 ve GMP Uyumlu Hazır Görsel Denetim Sistemi

FH Görsel Denetim sistemi, 21 CFR Bölüm 11 ve GMP uyumluluğunu destekleyecek şekilde yükseltilebilir; böylece Yaşam bilimi, farmasötik ve tıbbi cihaz üreticilerinin bu düzenlemelere uymak için görsel denetim sistemlerini üretim hatlarına kurmalarına olanak sağlanır.

Yazılım Özellikleri

- Denetim geçmişi raporu

- Denetim geçmişi görüntüleyicisi

- Geliştirilmiş parola güvenliği

- Şifrelenmiş dosyalar

- Kullanıcı erişim kontrolleri

- Çoklu oturum açmaya hazır

- HMI Entegrasyonu

Digimarc dijital filigran kod çözme

Silindirik ve Esnek Paketlemede benzersiz kod çözme

Şarj edilebilir batarya hücrelerinin görünüm denetimi

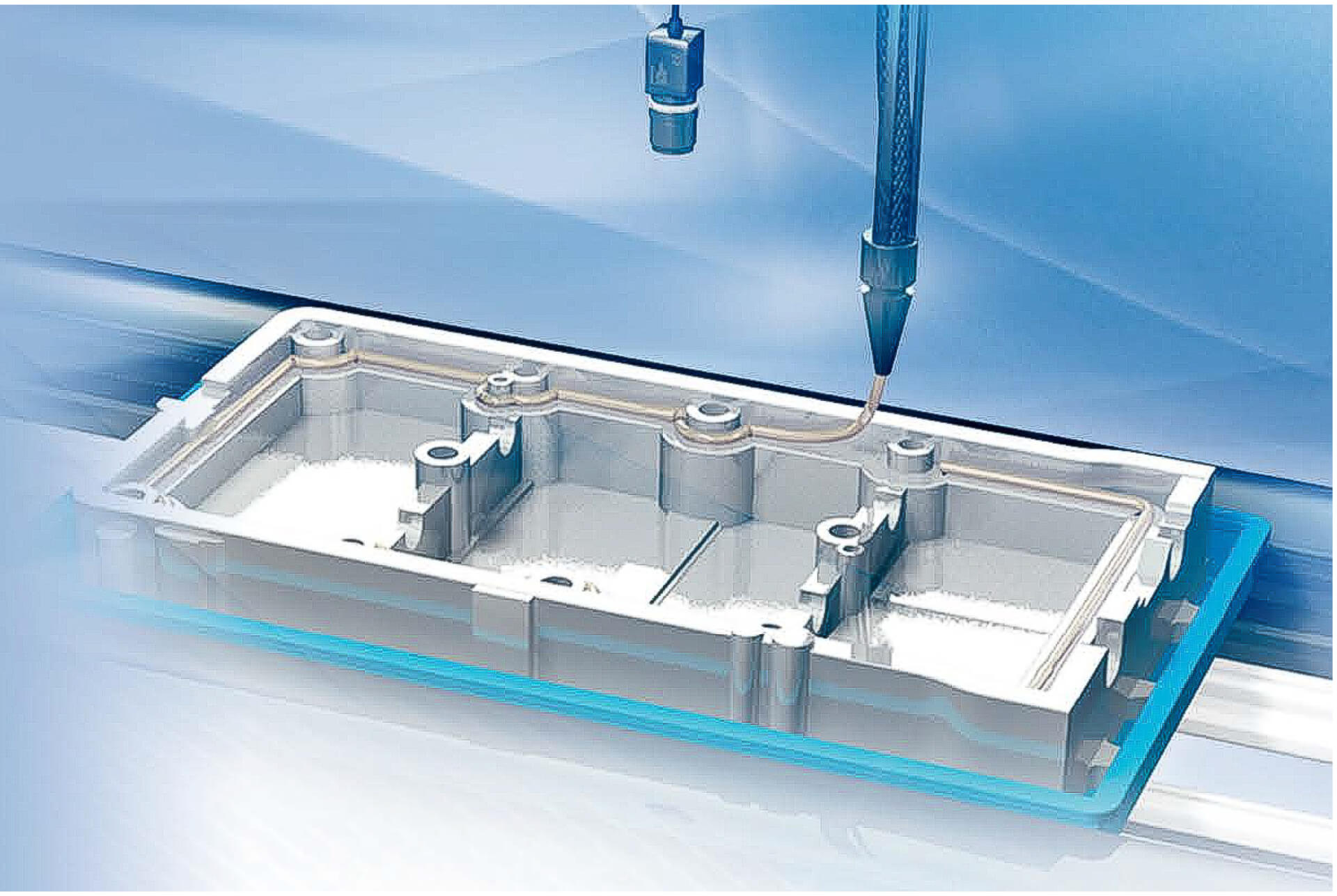

Tutkal Damlası Denetimi

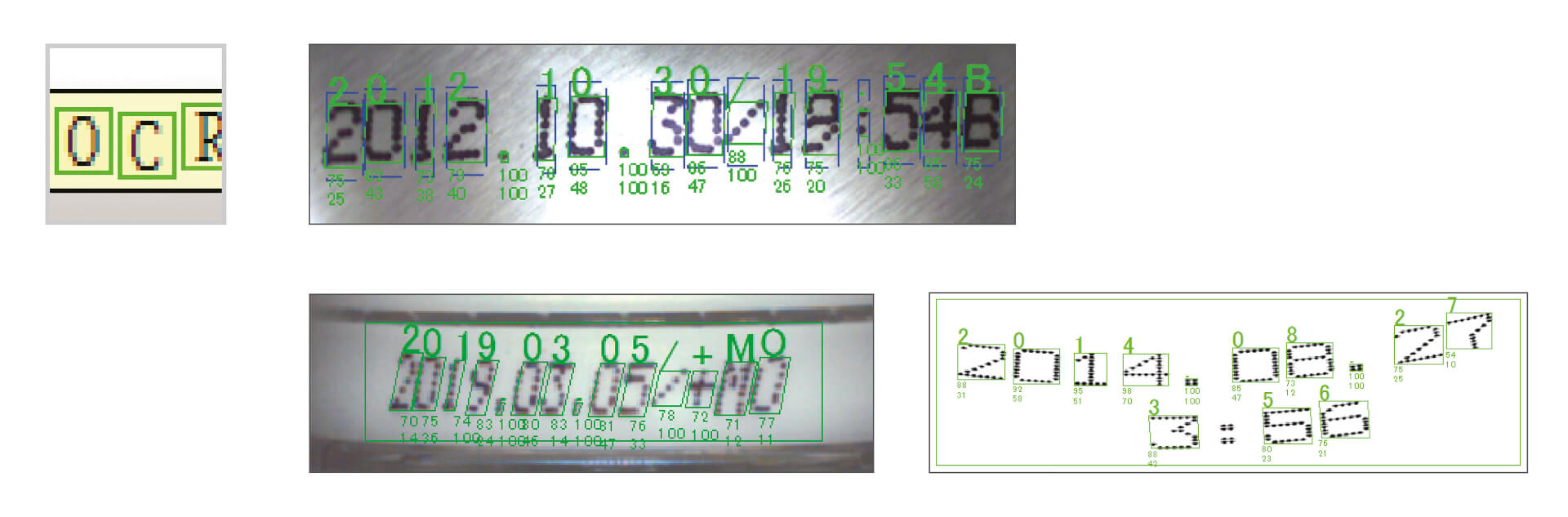

Okunması zor karakterleri güvenilir bir şekilde okur

Lens Selector

Videolar

-

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

02:05

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

-

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

05:58

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

-

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:56

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:58

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:Özellikler ve sipariş bilgisi

| Ürün | Performance | Processor family | Operating system | Memory | AI Scratch detection filter | AI FineMatching | Number of cameras | Integrated monitor | Communication port(s) | Output type | Application | Açıklama | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (ECC) | No | No | 4 | No | EtherCAT Slave, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 2 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH-Lite controller, standard grade, box type, 2 camera, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 4 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Counting, Defect inspection, Measurement inspection, OCR / OCV | FH-Lite controller, standard grade, box type, 4 camera, , W10 IoT Enterprise LTSC 2019 64bit |

|

Sektördeki ilk yapay zeka donanımlı hata algılama özelliğine sahip yeni FH görsel denetim sistemini

Yardımcı Olmak İçin Buradayız

Sorunuz mu var? Uzmanlarımız her adımda size yardımcı olmaya hazır.

İletişime geçin FH Görsel Denetim Sistemi

Teşekkür ederiz. Talebiniz konusunda en kısa sürede bilgilendirileceksiniz.

Teknik zorluklar yaşamaktayız. Form gönderme işleminiz başarılı olmadı. Lütfen özürlerimizi kabul edin ve daha sonra tekrar deneyin. Detaylar: [details]

DownloadIçin teklif FH Görsel Denetim Sistemi

Bu form ile seçtiğiniz ürün için bir teklif isteyebilirsiniz. * ile işaretli bölümleri doldurmak zorunludur. Kişisel bilgileriniz gizli kalacaktır.

Talebiniz için teşekkür ederiz. En kısa zamanda size bilgi verilecektir.

Teknik zorluklar yaşamaktayız. Form gönderme işleminiz başarılı olmadı. Lütfen özürlerimizi kabul edin ve daha sonra tekrar deneyin. Detaylar: [details]

DownloadYüklenenler

Bu sayfadaki içeriğe için lütfen oturum açın veya kaydol edinin

Bu sayfadaki içeriğe için lütfen oturum açın veya kaydol edinin

Bu sayfadaki içeriğe için lütfen oturum açın veya kaydol edinin

İlgili Ürünler

Yardıma mı ihtiyacınız var?

Yardımcı olmak için buradayız! Bize ulaşın, uzmanlarımız işletmeniz için en iyi çözümü bulmanıza yardımcı olsun.

İletişime geçin FH Görsel Denetim Sistemi

Teşekkür ederiz. Talebiniz konusunda en kısa sürede bilgilendirileceksiniz.

Teknik zorluklar yaşamaktayız. Form gönderme işleminiz başarılı olmadı. Lütfen özürlerimizi kabul edin ve daha sonra tekrar deneyin. Detaylar: [details]

DownloadIçin teklif FH Görsel Denetim Sistemi

Bu form ile seçtiğiniz ürün için bir teklif isteyebilirsiniz. * ile işaretli bölümleri doldurmak zorunludur. Kişisel bilgileriniz gizli kalacaktır.

Talebiniz için teşekkür ederiz. En kısa zamanda size bilgi verilecektir.

Teknik zorluklar yaşamaktayız. Form gönderme işleminiz başarılı olmadı. Lütfen özürlerimizi kabul edin ve daha sonra tekrar deneyin. Detaylar: [details]

Download