Otomasyon Blog Sayfası

Optimizasyondan otonomiye - OMRON'dan 2025 için en iyi beş üretim otomasyonu trendi

4 Ocak 2025, Cumartesi 2025'e adım atarken endüstriyel otomasyon dünyası çağ atlamaya yaklaşıyor. OMRON'un teknolojik gelişmeleri toplumsal değişimle ilişkilendiren SINIC Teorisine göre, artık Optimizasyon Toplumundan Otonom Topluma geçiş yapıyoruz. 1970 yılında OMRON'un kurucusu Kazuma Tateishi tarafından geliştirilen bu teori, yeniliğe kılavuzluk etmek için gelecekteki toplumsal ve teknolojik gelişmeleri öngörüyor. Optimizasyon aşamasında süreçlerin geliştirilmesi, verimliliğin artırılması ve operasyonların iyileştirilmesi için teknolojinin kullanılmasına odaklanılıyordu. Ancak Otonom Toplum, yepyeni bir çağ demek: Sistemlerin yalnızca verimli bir şekilde çalışmakla kalmayıp kendi kendini düzenleyen, kendi kendine öğrenen ve bağımsız karar verme yeteneğine sahip olduğu bir çağ.

Teknoloji hedefinin ötesinde: Endüstriyel otomasyon, operasyonel mükemmellikle buluştuğunda ne olur?

30 Kasım 2024, Cumartesi Son birkaç yılda teknolojide hızlı gelişmeler yaşandı ve yapay zekanın yükselişi önemli bir trend olarak öne çıktı. Birleşik Krallık, ABD ve Kanada'da üreticiler arasında yapılan bir ankette, katılımcıların %70'i operasyonlarına bir tür yapay zeka uyguladıklarını belirtti. Özellikle üretim sektörleri otomasyon ile büyük avantajlar elde edebileceğinden yeni teknolojileri benimsemeye yönelik güçlü bir istek söz konusudur.

Başarılı dijitalleşmenin ilk adımlarını atmak

12 Kasım 2024, Salı Dijital bir fabrika inşa etmek nihai bir hedef veya kendi başına bir neden değildir. Dijital fabrika, üretim işletmelerine pazardaki değişikliklere yanıt verme esnekliği sağlayan bir araçtır. Bu, inovasyon trendleri veya maliyet artışları gibi değişiklikler için yiyecek-içecek, kişisel bakım, ilaç veya otomotiv sektörlerinde kullanılabilir.

PPWR: Zincirler arası iş birliği, izlenebilirlik ve akıllı paketleme neden kritiktir?

24 Eylül 2024, Salı Eurostat rakamlarına göre 2021 yılında AB'de yaşayan insanlar kişi başına 188,7 kg ambalaj atığı oluşturdu ve bu sayı, 2011'e kıyasla yaklaşık 32 kg fazla. Bu süre içinde plastik ambalaj atık miktarı %27 arttı. Geri dönüşüm oranları da artmış olmasına rağmen plastik ambalajların büyük bir kısmı hala geri dönüştürülmemektedir; en son istatistikler, Avrupa'da plastikler için %50 geri dönüşüm oranına yalnızca bir avuç ülkenin ulaşabildiğini gösteriyor. Mevcut yasal çerçevenin ambalaj atıklarının azaltılmasında iyileşme sağlamadığını kabul eden Komisyon, 2022 yılında 2018 tarihli Ambalaj ve Ambalaj Atıkları Mevzuatı (PPWR) direktifinde bir revizyon yapılmasını önermiştir.Revize edilen PPWR'nin yıl sonu itibarıyla yürürlüğe girmesi ve ambalajların tasarlanma, tüketilme ve bertaraf edilme süreçlerini kökten değiştirmesi bekleniyor. Güncellenen mevzuatın kapsamı geniş olsa da temel amaç, üretilen ambalaj atığı miktarını azaltmak ve ambalajların geri dönüştürülebilirliğini artırmaktır.

Verimlilik tıkanıklığından kaçınmak: Şirketler robot planlarını neden ertelememelidir?

24 Eylül 2024, Salı Yenilikçi teknolojilere yapılan yatırımları geciktirmek birçok riskle ilişkilidir. Bu konuda hâlâ tereddüt eden şirketler kendilerine üç soru sormalıdır.Avrupa ekonomisi büyüme, istikrar ve rekabet gücünü etkileyen çeşitli güçlüklerle karşı karşıya. Örneğin Avrupa, dünyadaki en yaşlı nüfuslardan birine sahip. Yaşlanan iş gücü, sosyal güvenlik sistemleri üzerindeki yükü artırıyor ve iş gücü tedarikini azaltarak ekonomik büyümeyi potansiyel olarak yavaşlatıyor. Ayrıca, AB'nin Yeşil Mutabakat'a ve 2050 yılına kadar karbon nötrlüğünün sağlanmasına bağlılığı çeşitli sektörlerde önemli yatırımlar ve yapısal değişiklikler yapılmasını gerektiriyor. Bunun yanı sıra finansal endişeler nedeniyle yatırım yapma isteksizliği de söz konusu. McKinsey Global Institute (MGI) tarafından kısa süre önce yapılan bir araştırma, 1 milyar dolardan fazla gelir elde eden büyük Avrupalı firmaların ABD'deki benzer firmaların gerisinde kaldığını ortaya çıkardı. Yılda toplam 400 milyar dolar daha az yatırım yapıyor ve üçte bir oranında daha yavaş büyüyorlar.Bu yatırım hevessizliği; rekabet gücü, sürdürülebilirlik ve itibar açısından dezavantajlar, yetersiz verimlilik ve yeni nitelikli çalışanların ilgisini çekmede azalan başarı gibi kısa ve uzun vadeli etkileri olan çeşitli sorunlara yol açabiliyor. Yenilikçi robot teknolojisi bu tür gelişmelerle mücadele edebiliyor olsa da iyi düşünülmüş bir finansman kapasitesi de gerektiriyor. Bu nedenle, şu anda yatırımlarını kısıtlayan şirketler, bunun uzun vadede kısa vadeli tasarruflardan daha fazla olumsuz sonucu olup olmayacağını acilen kendilerine sormalıdır. Aşağıdaki üç soru, bu hususların odak noktası olmalıdır:

Açık standartlarla dijitalleştirmek: Gece rahat uyumanın anahtarı

2 Eylül 2024, Pazartesi Yaptığım tahminlere bağlı kalabilir miyiz? Teslim tarihine uyabilecek miyiz? Bundan emin olabilecek kadar bilgiye sahip miyim? QCDE (kalite, maliyet, teslimat süresi ve çevresel etki) açısından hedeflerimize göre ve rakiplerimizle karşılaştırıldığında fabrikanın durumu ne? Geceleri fabrika yöneticilerinin uykusunu kaçıran bu endişeler, dijitalleştirme yoluyla çözülebilir. Dijitalleştirilmiş bir üretim ortamında fabrika yöneticilerinin bilinmeyenler, riskler ve ortaya çıkabilecek durumlar hakkında endişelenmesine gerek yoktur. Dijitalleştirme, belirsizliği ortadan kaldırır ve performans odaklı optimizasyon sağlar. Fabrika yöneticilerinin kaliteyi iyileştirmelerine, maliyetleri düşürmelerine, teslim sürelerini kısaltmalarına ve çevresel etkileri azaltmalarına yardımcı olabilecek bilgileri sağlar. Dijitalleştirilmiş bir fabrikanın yöneticisi, gecenin bir yarısı endişe içinde uyanmaz ancak uyansa dahi cep telefonundan hızlıca her şeyin olması gerektiği gibi ilerlediğini kontrol edip kendini güvende hissedebilir. Ancak endişeyle geçen uykusuz gecelerden mışıl mışıl uyunan gecelere giden yol kolay değildir. Açık konuşmak gerekirse dijitalleştirme oldukça yorucu bir süreç olabilir. Proje liderleri nadiren temiz bir sayfada çalışma lüksüne sahiptir; çoğu zaman eski teknolojilerin birbirine yamalandığı bir kırkyama üzerinde çalışmaları gerekir. Daha önce hiç veri kaydetmemiş, henüz ortada veri haberleşme protokolleri dahi yokken üretilen makinelerden oluşan üretim hatlarını dijitalleştirmek için çaba gösterirler. Tüm bunlar bir araya geldiğinde ciddi bir OT ve IT entegrasyonu sorunu ortaya çıkar.

Dinamik hat kenarı ikmal: günümüzün üretim zorluklarına stratejik bir yanıt

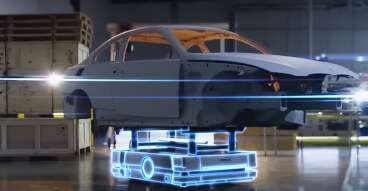

15 Temmuz 2024, Pazartesi Üreticilerin, özelleştirme ve iş gücü eksikliğinin getirdiği zorlukların üstesinden gelirken verimli ve rekabetçi kalmaları için hat kenarı ikmal sistemleri ve uygulamaları üzerinde yeniden düşünme zamanı geldi. Cevap AMR'ler ve cobot'larda olabilir mi? Özelleştirme trendi, üreticiler için çok sayıda operasyonel zorluğu beraberinde getirmiştir; daha geniş bir komponent ve malzeme yelpazesi bulundurma gerekliliği, geleneksel sistemlerin verimli bir şekilde yönetmekte zorlandığı bir değişkenliğe yol açmaktadır. Bu durum envanter maliyetlerinin, tedarik sürelerinin ve üretimde gecikmelerin artmasına neden olabilir. Veriler, özelleştirmenin üretim operasyonları üzerindeki etkisinin altını çizmektedir: Üreticiler daha uzun tedarik süreleri, daha yüksek üretim maliyetleri ve çok sayıda envanteri yönetme gerekliliği ile karşı karşıya kaldığını bildirmiştir. Bu veriler, özelleştirmenin getirdiği somut zorlukları resmederken bu karmaşıklığı verimli bir şekilde yönetmek için yenilikçi yaklaşımların gerekliliğini göstermektedir.

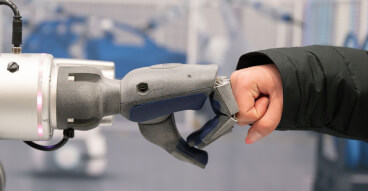

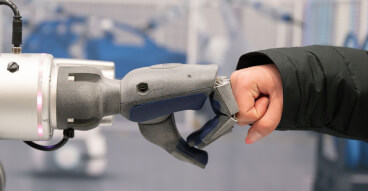

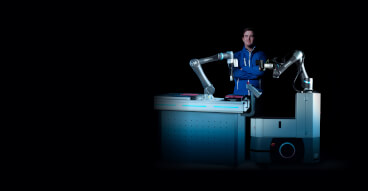

Robotic Trends 2024: Tam potansiyele ulaşmak için gereken basit ve esnek uygulama

3 Temmuz 2024, Çarşamba Yük taşıyıcıdan iş arkadaşına ve ekip oyuncusuna: Robotların rolü son yetmiş yıl içinde önemli ölçüde değişti. Yapay zeka daha fazla olasılık yaratıyor olsa da insanlar belirleyici faktör olmaya devam ediyor. Robotlar mı insanlar mı: Gelecekte üretimi kim şekillendirecek? 1954 yılında George Devol'un programlanabilir manipülatörün patentini almasından beri bu soru tartışmalara yol açmıştır. Devol'un Unimate adlı robotu tehlikeli görevleri güvenli bir şekilde yerine getirerek sektörde devrim yaratmış ve odak noktasının "insanlara karşı robotlar" değil, "robot + insan = verimlilik" olduğunu vurgulamıştır. 70 yılı aşkın bir sürede endüstri talepleri; esneklik, ölçeklenebilirlik, uyarlanabilirlik ve sürdürülebilirliğe öncelik verecek şekilde değişmiştir. Robotlar, insanların katma değerli faaliyetlere odaklanmaları için yükünü azaltan görevleri yerine getirmektedir.

Noktaları birleştirmek: Rekabet avantajı için besleme faaliyetlerini otomatikleştirmek

18 Haziran 2024, Salı Robotlardaki gelişmeler, iş gücü eksikliklerini ele alırken emniyeti, verimliliği ve kaliteyi artırabilen esnek hat kenarı ikmal ve taşıma sistemlerinin geliştirilmesini kolaylaştırmaktadır. Fabrika otomasyonu genellikle noktalarla başlar. Bu da yatay paketleme, enjeksiyon kalıplama, blister paketleme, şişeleme, paletleme veya diğer temel üretim süreçleri gibi karmaşık ve gözle görülür değer katan görevleri yerine getiren başlıca tesis demektir. Bu noktaları bir araya getiren çizgiler (kullanım, yükleme ve besleme sistemleri) üzerinde genellikle çok düşünülmediğinden bu faaliyetler çoğunlukla manuel olarak gerçekleştirilir. Otomasyon için harcama yapmak yerine üretim hattına ham madde yükleme veya makineye komponent besleme gibi işlemlerin operatör tarafından yapılması ilk bakışta daha kolay ve ucuz görünebilir. Ancak bu, otomatik hat kenarı ikmal ve taşımanın verimlilik, ürün kalitesi, ölçeklenebilirlik, sağlık ve emniyet açısından sağlayabileceği birçok iş avantajını gözden kaçıran, ileriyi göremeyen bir bakış açısıdır. Mevcut iş gücü krizinin üretim sektörü üzerindeki baskısı göz önüne alındığında, bu bakış açısı da gittikçe geçmişte kalmaktadır.

EV üreticilerinin sürdürülebilir bir geleceğe ulaşma yolculuğunda karşılaştığı en büyük 4 zorluk

17 Haziran 2024, Pazartesi Elektrikli araçlar (EV'ler) son yıllarda spesifik bir pazar olmaktan çıkıp sektörde büyük bir güç haline geldi. IEA Küresel EV Görünümü 2024'e göre, 2023 yılı itibarıyla satılan yaklaşık her beş araçtan biri elektrikli araçtır ve elektrikli araç satışları 3,5 milyon birim artmıştır, yani önceki yıla göre %35'lik bir artış elde edilmiştir. Bu artışın devam etmesi bekleniyor ve yükselen pazarlardaki satışların 2024 yılında, 2023'e göre %40'lık bir artışla 1 milyon birimi aşacağını belirten tahminler yapılıyor. Dünya çapındaki hükümetler, CO2 emisyonlarını azaltmak için baskı yapıyor ve bu da elektrikli araçlara geçişi hızlandırıyor.Peki bu, otomotiv üreticileri için ne anlama geliyor? Birincisi, ağırlıklı olarak elektrikli filolar tasarlamaya ve üretmeye odaklanmaları gerektiği anlamına geliyor, birçok üretici halihazırda bu yönde harekete geçmiş durumda. İkinci olarak ise yeni üretim hatları oluşturmak ve yeni üretim süreçlerinde ustalaşmak gerekiyor, bu da epey zorlayıcı olabiliyor.Güvenilir bir otomasyon iş ortağı burada devreye giriyor. Otomasyon konusunda bir uzmanla iş ortaklığı kurmak, sektör genelindeki bu geçişin karmaşıklıklarını yönetmeye yardımcı olabilir. Geniş bir teknoloji portföyü, küresel destek ve otomotiv alanındaki engin uzmanlık bilgileriyle OMRON, elektrikli araçlara geçiş yolculuklarında üreticilere rehberlik etmeye hazırdır.Bu blog yazısında, EV (elektrikli araç) üretim sektöründeki en büyük zorluklar ve OMRON ile iş ortaklığı kurmanın bu zorluklara nasıl etkili çözümler sağlayabileceği açıklanacaktır:

Değişimin aracısı olarak akıllı otomasyon

31 Mayıs 2024, Cuma Üretim sektörü, küresel sera gazı emisyonlarının yaklaşık dörtte birinden sorumludur¹ ve bu da onu, karbon emisyonlarına en fazla katkıda bulunan ikinci sektör olan taşımacılıkla aynı sıraya koymaktadır. Bu durum üretim sektörünün karbon ayak izini azaltmanın, iklim değişikliği üzerindeki etkimizi azaltmada önemli bir rol oynayacağı anlamına gelmektedir.Üretim sektörünün artık bir sorun kaynağı olmak yerine çözüm kaynaklarından biri olmanın yanı sıra, iklim değişikliğini ele alıp, süreçteki değişim aracısı olarak otomasyonu kullanıp potansiyelini ortaya çıkarmaya başlamasının zamanı geldi.Bu; kurucumuzun, bir işletme olarak faaliyet gösterdiğimiz toplum yararına işler yama sorumluluğumuza olan inancını yansıtmaktadır. 90 yıldan uzun bir süre önce OMRON, kurucusu Kazuma Tateishi'nin daha iyi bir dünya için teknolojiden faydalanma vizyonuyla ortaya çıktı.Tateishi'nin "yaşamları iyileştirme ve daha iyi bir topluma katkıda bulunma" konusundaki inancı, bir toplum olarak karşılaştığımız iklim zorlukları göz önüne alındığında şu ana kadar hiç olmadığı kadar büyük bir öneme sahiptir. Peki, üretim nasıl olumlu bir fark yaratabilir?

Bozulmadıysa bile kurcalamanız gerekebilir

4 Nisan 2024, Perşembe Akıllı enerji yönetimi ile FMCG üretimini daha sürdürülebilir hale getirme

Optimizasyondan otonomiye - OMRON'dan 2025 için en iyi beş üretim otomasyonu trendi

4 Ocak 2025, Cumartesi 2025'e adım atarken endüstriyel otomasyon dünyası çağ atlamaya yaklaşıyor. OMRON'un teknolojik gelişmeleri toplumsal değişimle ilişkilendiren SINIC Teorisine göre, artık Optimizasyon Toplumundan Otonom Topluma geçiş yapıyoruz. 1970 yılında OMRON'un kurucusu Kazuma Tateishi tarafından geliştirilen bu teori, yeniliğe kılavuzluk etmek için gelecekteki toplumsal ve teknolojik gelişmeleri öngörüyor. Optimizasyon aşamasında süreçlerin geliştirilmesi, verimliliğin artırılması ve operasyonların iyileştirilmesi için teknolojinin kullanılmasına odaklanılıyordu. Ancak Otonom Toplum, yepyeni bir çağ demek: Sistemlerin yalnızca verimli bir şekilde çalışmakla kalmayıp kendi kendini düzenleyen, kendi kendine öğrenen ve bağımsız karar verme yeteneğine sahip olduğu bir çağ.

2024 için otomasyonda neler bekleniyor? OMRON Europe'tan altı tahmin

13 Aralık 2023, Çarşamba Son birkaç yıldaki art arda gelen olumsuz gelişmeler, artan jeopolitik ve ekonomik risklerin yeni bir dönemini beraberinde getirdi. Bu durum, üreticileri iş modellerine dayanıklılık ve esneklik kazandırmaya, küresel tedarik zincirlerini ve ilişkilerini yeniden düşünmeye sevk ediyor. Aynı zamanda, ESG prensiplerini, operasyonel karar alma süreçlerine dahil etmeleri konusunda baskı artıyor. Yapay zeka, veri bilimi ve dijital ikizlerin yanı sıra algılama, izleme ve görsel denetim teknolojileri; üretim endüstrisinin bu yeni gerçeğe uyum sağlamasına yardımcı olacak otomasyon ve kontrol çözümlerini geliştirmek için temel unsurlar olacak. Bu bağlamda, 2024 ve sonrasında endüstriyel otomasyonu etkileyecek ve şekillendirecek altı temel trendi paylaşmak istiyorum.

İş gücüne güç katma: OMRON'un Avrupa üretiminde beceri geliştirme yaklaşımı

6 Eylül 2023, Çarşamba OMRON'un yeni nesle güç kazandıran becerileri geliştirmeye olan sarsılmaz bağlılığını ele alırken sektörde dönüşüm dolu bir yolculuk başlıyor. Bu yolculuk, Dördüncü Sanayi Devrimi'nin (4IR) tüm potansiyelini ortaya çıkarırken diğer yandan cesurca Beşinci Sanayi Devrimi'ne (5IR) doğru ilerliyor.Akademik toplantı salonlarında, vizyoner iş liderlerinin yönetim kurulu odalarında ve ileri görüşlü siyasetçilerin ofislerinde hararetli tartışmalar yaşanıyor. Bütün bunların merkezinde Dördüncü Sanayi Devrimi, 4IR ya da diğer adıyla Endüstri 4.0'dan, yaşadığımız dünyayı değiştirecek olan Endüstri 5.0'a geçiş yer alıyor.Tarihsel olarak İlk Makine Çağı Sanayi Devrimi'yle, İkinci Makine Çağı da elektrikle başladı. Ardından elektronik ile Üçüncü, bir platform olarak internet ile de Dördüncü Makine Çağı'na girdik. Günümüzde ise insan ile makine arasındaki uyumlu iş birliğinin ve endüstrinin topluma katkılarının ön plana çıktığı Beşinci Makine Çağı'na doğru ilerliyoruz. Şimdi yalnızca uyum sağlamakla kalmayıp liderlik etme, öncülük yapma ve yeniliğin sınır tanımadığı bir gelecek yaratma zamanı. Dünya Ekonomik Forumu'nun kurucusu ve yönetim kurulu başkanı Klaus Schwab şöyle söylüyor: "Yaşama, çalışma ve birbirimiz ile ilişki kurma şeklimizi kökten değiştirecek bir teknolojik devrimin eşiğindeyiz. Ölçeği, kapsamı ve karmaşıklığı nedeniyle bu dönüşüm, insanlığın daha önce deneyimlediği her şeyden farklı olacak. Dünyamız dönüştürücü bir süreçten geçiyor. Akıllı teknoloji, makineler arası (M2M) haberleşme ve IoT entegrasyonuyla geleneksel endüstriyel uygulamaların otomasyonu sayesinde küresel üretim gelişiyor. Bu sinerji, daha yüksek düzeyde otomasyon ve sorunsuz haberleşmenin yanı sıra zorlukları otonom olarak analiz edip tanılayan akıllı makineleri destekliyor.Yapay zekanın yükselişi tartışmalara yol açarak toplumsal dokumuzdaki daha derin dönüşümlerin sinyalini veriyor. Bu dinamik ortamda ilerlerken inovasyonu benimsemeye ve geleceğimizi yeniden şekillendirmeye hazırız.

Kırmızı ışıklardan robotlara: OMRON, inovasyonla geçen 90 yılı kutluyor

6 Haziran 2023, Salı Bu yıl Kuruluş Gününde OMRON, teknolojinin sınırlarını zorladığı 90 yıla dönüp bakarken bir yandan da sürdürülebilirlik, dijitalleşme ve insan-makine iş birliğini temel alan otomasyon inovasyonu geleceğini sabırsızlıkla bekliyor.10 Mayıs Kuruluş Günümüz kutlu olsun… Her yıl 10 Mayıs günü, muhtemelen OMRON için takvimdeki en önemli gündür. Bu tarihte, dünyanın dört bir yanındaki 30.000 OMRON çalışanı, şirketin kurucusu olan Kazuma Tateishi'nin hayatını ve mirasını kutlar. Bunu Tateishi'nin daha iyi bir dünya yaratmak için teknolojiyi kullanma vizyonuna bağlılıklarını tazeleyerek ve genellikle kendi topluluklarındaki gönüllü projeler ve yardım projelerine katılmak aracılığıyla toplum yararına işler yaparak gerçekleştirirler. İnovasyonda Kilometre Taşları OMRON'un inovasyon yolculuğu, röntgen fotoğrafı için yüksek hassasiyetli bir zaman rölesi geliştirmesiyle 1933 yılında başladı. Bu da şirketin toplumsal ihtiyaçları ele alma konusundaki ilk katkısı oldu. 1960 yılında OMRON, dünyanın ilk temassız proximity switch'ini tanıtarak gelişmiş seri üretim yeteneklerinde çığır açtı. O günden bu yana OMRON; ilk otomatik trafik sinyali, insansız tren istasyonu sistemi, giyilebilir tansiyon kontrol cihazı, ultra yüksek hızlı bulanık lojik kontrolörü ve otomatik kanser hücresi tanılama ekipmanı gibi çığır açan teknolojileri tanıtmayı sürdürdü.

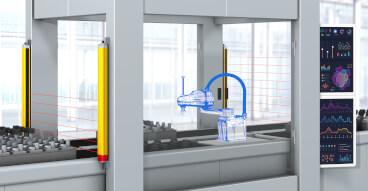

Robot sistemlerindeki Yapay Zeka (AI) fonksiyonel emniyet kısımlarını yönetebilir mi?

13 Nisan 2023, Perşembe Yazarlar: OMRON Europe Emniyet Ürün Pazarlama Müdürü JOSEP Plassa ve OMRON Geliştirme Merkezi Müdürü Atsushi OshiroRobotlar ve yapay zeka sistemleri, endüstriyel üretim tesislerinin ayrılmaz bir parçası haline gelmiştir. Robotları kullanırken çalışanların emniyetini sağlamak için ayrıntılı bir risk değerlendirmesi gereklidir. Bu değerlendirme, robotların otonom kontrol eylemlerini (Ortam tanıma, Eylem planlama, Yol oluşturma, Hareket kontrolü ve Ölçüm) belirlemek için kullanılan beş ana unsuru inceleyen Fonksiyonel Emniyet açısından gerçekleştirilir.

Yapay Zeka: Beni aptal sanmayın

8 Şubat 2023, Çarşamba On yıl önce kendi fabrikamızdaki makinelerin ne kadar akıllı olduğu konusunda bir hayli gururluydum. Şimdi, "akıllı" kavramına dair bugünkü algımı göz önünde bulundurduğumda aslında bir hayli aptal olduklarını fark ediyorum.Neden? Çünkü yapmak üzere tasarlandıkları şeyi yapmalarına rağmen, beklenmedik ya da sıra dışı bir durumla karşılaştıkları anda afallıyorlardı. Operatöre "Benim sorunum ne?" sorusunu sormak durumunda kalıyorlardı.Sorun giderme ve makinelerin onarılıp çalıştırılması, akıllı bireyleri gerektiriyordu. Son derece yetenekli operatörleri... Deneyimli yazılım ve donanım mühendislerini... Sorun şu ki son on yılda bu kişilerin bulunması gittikçe daha da zorlaştı. Sektöre giren yeni yeteneklerin sayısı, emeklilik yaşına ulaşan çalışanların sayısını dengeleyecek kadar yeterli değil. İşten ayrılan emekliler yılların tecrübesinin doruk noktası olan, iş başında emek vererek kazandıkları bilgileri yanlarında götürürler. Ayrılan her bir çalışanla birlikte işletmeler daha az verimli ve daha az yetenekli bir iş gücü olasılığıyla karşı karşıya kalır.

Net sıfıra giden yol: taktikler konusu

1 Şubat 2023, Çarşamba Üretimin net sıfıra ulaşabildiği bir gelecek için değer zinciri, otomasyonla dönüştürülmelidir.Haziran 2022'de New Scientist, dünyanın en büyük şirketlerinin üçte birinin net sıfır hedefi olduğunu, yani geçen yıldaki aynı döneme göre önemli ölçüde daha fazla şirket olduğunu bildirdi.İvmedeki artış olumlu bir gelişme olsa da makale, şirketlerin net sıfıra ulaşma planlarındaki ayrıntıların düzensiz olmasından da bahsediyor.Bu durum pek şaşırtıcı değil. Net sıfır stratejisi oluşturup uygulamak, özellikle de GHG emisyonlarının %80'i Kapsam 3'e giren şirketler için oldukça zordur. Bu emisyon, değer zincirinin girişinde ya da çıkışında oluşmaktadır. Bu, tedarik zinciri ve ürün dağıtım lojistiği hem uzun hem de karmaşık olan FMCG şirketleri için daha da büyük bir zorluktur.Bu işletmelerin çoğu, değer zincirinden karbonu çıkarması ve döngüsel bir değer zinciri elde etmesi gerektiğini biliyor. Bunu gerçekleştirmek için bir stratejileri de var. Bu strateji genel olarak, kaynak ve enerji kullanımının optimizasyonunu, yüksek emisyonlu ürünlerin ve süreçlerin değiştirilmesini ve atıkların ortadan kaldırılmasını kapsıyor.Buradaki asıl zorluk, niyeti eyleme dönüştürmektir. İşte tam da bu noktada otomasyon, çok kritik bir role sahiptir.Veri toplama ve analiz, net sıfıra başarılı bir geçişin anahtarıdır. Bu olmadan şirketler; başlangıç noktalarını, geliştirmeleri gereken yerleri, gelişip gelişmediklerini ve geliştilerse bunun ne kadar etkili olduğunu nasıl bilebilir? Sağlam veriler, taahhüdü değişim haline getirir, hem güvenilir hem de özgüvenli bir şekilde paydaşlarla iletişim kurmayı sağlar ve iklime yönelik çalışmaların gerçekleşmesine olanak tanır.

Otomasyon sayesinde enerji ve yakıt krizinin üstesinden gelme

7 Aralık 2022, Çarşamba Yükselen fiyatlara karşı koymak ve çevreyle ilgili hedefleri karşılamak adına endüstri şirketlerinin, tek kaynaklı otomasyon teknolojilerinin sürdürülebilirlik stratejilerine nasıl katkıda bulunabileceğini incelemesi gerekir.Yüksek enerji ve yakıt fiyatları, hem evlerimizde hem de endüstrilerimiz de zorluklara yol açıyor. Bu durum, mali planları ve cüzdanları olumsuz yönde etkilemekle kalmıyor, aynı zamanda aşırı yüksek fiyatlar nedeniyle bazı şirketler imalatı durdurmaya zorlanıyor. Make UK tarafından gerçekleştirilen bir ankette imalatçıların %42'si, elektrik faturalarının geçtiğimiz 12 ay içinde %100 zamlandığını belirtirken %32'si ise gaz fiyatlarının geçtiğimiz sene içinde %100 zamlandığını dile getiriyor. Endişe verici bir orana sahip %12'lik dilim ise yükselen enerji faturalarının doğrudan sonucu olarak işten çıkarmalara başladığını belirtti.Ukrayna'daki savaş, Covid-19 salgını ve gaz fiyatları krizin yalnızca birkaç nedeni; tüm bu nedenler bir araya gelerek tüm sektörleri ve enerji fiyatlarından tedarik zincirlerine kadar her alanı etkiliyor. Peki imalat şirketlerinin bu durumda ne yapması gerekiyor? Kapsamlı otomasyon stratejileri, daha yüksek esneklik ve enerji verimliliği açısından büyük bir önem taşıyor. Buna, sensör ve görsel denetim teknolojileriyle birlikte kullanılan yenilikçi robotların yanı sıra makine seviyesinde gerçek zamanlı yapay zeka (AI) da dahil. Ayrıca imalat tesislerinden alınan gerçek zamanlı veriler, anormallikleri tespit etme ve genel ekipman etkililiğini (OEE) artırma konusunda da yardımcı olabilir.

Gelecek intralojistiğe mi yöneliyor? Daha fazla verimlilik için ipuçları

15 Kasım 2022, Salı Bazen büyük resme o kadar çok odaklanırız ki akıllı üretimi simgeleyen küçük ve çok önemli olan süreçleri unuturuz. Buna örnek olarak intralojistiği, yani bir şirketin tesislerinde veya üretim salonunda gerçekleşen malzeme ve ürün akışlarını verebiliriz. Kısa bir süre önce yapılan bir çalışma, ankete katılan şirketlerin yüzde 80'inden fazlasının, kalifiye çalışan eksikliği veya büyüme planları gibi zorlukların üstesinden gelmek için intralojistikte yapay zeka ve otomasyon kullanımının artmasını gerekli bulduğunu ortaya koydu.Pazar ve müşteri gereksinimlerini karşılamak, verimliliği artırmak ve daha sürdürülebilir olmak isteyen otomotiv şirketleri yeni fikirler üretmelidir. Enerji maliyetleri, gaz krizi ve yükselen enflasyon bu görevi daha da zorlaştırmaktadır. Yenilikçi otomasyon, dijitalleşme ve akıllı intralojistik yaklaşımlarını bir araya getiren akıllı fabrika konseptleri, değerli destekler sağlayabilir. Bazıları bu bağlamda Endüstri 4.0'dan bahsederken bazıları "geleceğin fabrikası", bazıları ise Endüstriyel Nesnelerin İnterneti'ni (IIoT) tercih ediyor. Ancak hangi yaklaşımı seçerseniz seçin, en önemlisi şimdi harekete geçmek ve güvenilir iş ortaklarıyla çalışmaktır. İntralojistik, değişimi hızlı bir şekilde başlatmak için iyi bir başlangıç noktasıdır çünkü acilen harekete geçilmesi gerekiyor. Şu anda birçok şirket, kalifiye çalışan eksikliği nedeniyle ciddi ölçüde kısıtlanmıştır. Mobil robotlar gibi modern teknolojiler çözüm sağlayabilir.

Adaptif yapay zeka denetimi esnek üretime nasıl katkıda bulunabilir?

4 Ekim 2022, Salı Günümüzde tüketiciler, kişisel ihtiyaçlarını ve isteklerini karşılamak için özelleştirilmiş ürünler talep ediyor. Üreticiler, "rafta saklamak için üretilmiş" ve "stoğa gönderilen" ürünler üretmek yerine bunları, "kişi için üretilmiş" ve "kişiye gönderilen" ürünler olacak şekilde özelleştirmelidir. Bu durum, üretimde çığır açmanın yanı sıra şirketleri süreçlerini yeniden düşünmeye zorlamaktadır. Aynı zamanda, sıfır şikayet ve sıfır hata sağlamak gerekir.İşinin ehli, deneyimli bir görsel denetimci hataları hemen tespit edebilir ancak bunun gibi rutin bir görev yorucudur ve özellikle birçok sektörde mevcut olan iş gücü yetersizliği nedeniyle üretimin her adımında gerçekleştirilemez. Ancak bu görev yüksek çeşitliliğe sahip düşük hacimli üretimde de otomatik hale getirilebilir mi? Akıllı bir görsel denetim sistemi veya "elektronik bir göz", tekrarlanabilirlik ve sağlamlık ek avantajlarıyla insan gözünün ayırt etme kabiliyetine sahip olabilir mi? En yeni yapay zeka özellikli adaptif denetim; gelişmiş esneklik, verimlilik ve uyarlanabilirlik ile otomatik kalite denetimi zorluklarının üstesinden gelebilir.

Yapay Zeka: umut, heyecan ve FOMO

22 Eylül 2022, Perşembe On yıl önce yapay zeka tabanlı projelerle ilgili aldığımız sorular, çoğunlukla bu konuya duyulan heyecan veya FOMO'dan kaynaklanıyordu. İnsanlara neden yapay zeka uygulamalarına girişmek istediklerini sorduğumda çoğu zaman aldığım cevaplar şunlardı: "patronum benden istediği için", "çok fazla veriye sahip olduğumuz için" veya "ilginç bir alan gibi göründüğü için". Bunların hiçbiri özellikle sağlam nedenler değildi ve yapay zeka uygulamalarının o sırada gerektireceği yüksek yatırıma değer sayılmazdı.Bu durum değişmektedir ve bu defa asıl itici güç, duyulan heyecan veya "FOMO" değil, umuttur. Müşteriler artık yapay zeka konusunda değil; kestirimci bakım, kalite kontrol veya süreç optimizasyonu hakkında onlara yardımcı olup olmayacağımızı soruyorlar. Bize, çözüm bulmamızı istedikleri bir sorunla geliyorlar. Yapay zekanın benimsenmesi artık bir gerekçe veya amaç değil. Aksine, yapay zeka bir "olanak tanıyıcı" haline geldi.Yiyecek ve içecek, ilaç, elektronik veya otomotiv sektörü fark etmeksizin nihai amaç aynıdır: Daha düşük maliyetle, daha az enerji ve daha az iş gücü kullanarak yüksek kaliteli, hatasız ürünler üretmek. Yapay zeka, bu hedeflere ulaşmaya yönelik bir dizi çözümden biri olabilir.

Otomasyon, sürdürülebilir paketlemeye uyum sağlıyor

16 Ağustos 2022, Salı Daha önce hiç internet üzerinden küçük bir ürün sipariş ettiğinizde ürünün balonlu naylon, hava dolu yastıklar veya kağıt parçacıkları içinde büyük bir kutuda geldiğini görünce öfkelendiniz mi?

Dinamik hat kenarı ikmal: günümüzün üretim zorluklarına stratejik bir yanıt

15 Temmuz 2024, Pazartesi Üreticilerin, özelleştirme ve iş gücü eksikliğinin getirdiği zorlukların üstesinden gelirken verimli ve rekabetçi kalmaları için hat kenarı ikmal sistemleri ve uygulamaları üzerinde yeniden düşünme zamanı geldi. Cevap AMR'ler ve cobot'larda olabilir mi? Özelleştirme trendi, üreticiler için çok sayıda operasyonel zorluğu beraberinde getirmiştir; daha geniş bir komponent ve malzeme yelpazesi bulundurma gerekliliği, geleneksel sistemlerin verimli bir şekilde yönetmekte zorlandığı bir değişkenliğe yol açmaktadır. Bu durum envanter maliyetlerinin, tedarik sürelerinin ve üretimde gecikmelerin artmasına neden olabilir. Veriler, özelleştirmenin üretim operasyonları üzerindeki etkisinin altını çizmektedir: Üreticiler daha uzun tedarik süreleri, daha yüksek üretim maliyetleri ve çok sayıda envanteri yönetme gerekliliği ile karşı karşıya kaldığını bildirmiştir. Bu veriler, özelleştirmenin getirdiği somut zorlukları resmederken bu karmaşıklığı verimli bir şekilde yönetmek için yenilikçi yaklaşımların gerekliliğini göstermektedir.

Robotic Trends 2024: Tam potansiyele ulaşmak için gereken basit ve esnek uygulama

3 Temmuz 2024, Çarşamba Yük taşıyıcıdan iş arkadaşına ve ekip oyuncusuna: Robotların rolü son yetmiş yıl içinde önemli ölçüde değişti. Yapay zeka daha fazla olasılık yaratıyor olsa da insanlar belirleyici faktör olmaya devam ediyor. Robotlar mı insanlar mı: Gelecekte üretimi kim şekillendirecek? 1954 yılında George Devol'un programlanabilir manipülatörün patentini almasından beri bu soru tartışmalara yol açmıştır. Devol'un Unimate adlı robotu tehlikeli görevleri güvenli bir şekilde yerine getirerek sektörde devrim yaratmış ve odak noktasının "insanlara karşı robotlar" değil, "robot + insan = verimlilik" olduğunu vurgulamıştır. 70 yılı aşkın bir sürede endüstri talepleri; esneklik, ölçeklenebilirlik, uyarlanabilirlik ve sürdürülebilirliğe öncelik verecek şekilde değişmiştir. Robotlar, insanların katma değerli faaliyetlere odaklanmaları için yükünü azaltan görevleri yerine getirmektedir.

Noktaları birleştirmek: Rekabet avantajı için besleme faaliyetlerini otomatikleştirmek

18 Haziran 2024, Salı Robotlardaki gelişmeler, iş gücü eksikliklerini ele alırken emniyeti, verimliliği ve kaliteyi artırabilen esnek hat kenarı ikmal ve taşıma sistemlerinin geliştirilmesini kolaylaştırmaktadır. Fabrika otomasyonu genellikle noktalarla başlar. Bu da yatay paketleme, enjeksiyon kalıplama, blister paketleme, şişeleme, paletleme veya diğer temel üretim süreçleri gibi karmaşık ve gözle görülür değer katan görevleri yerine getiren başlıca tesis demektir. Bu noktaları bir araya getiren çizgiler (kullanım, yükleme ve besleme sistemleri) üzerinde genellikle çok düşünülmediğinden bu faaliyetler çoğunlukla manuel olarak gerçekleştirilir. Otomasyon için harcama yapmak yerine üretim hattına ham madde yükleme veya makineye komponent besleme gibi işlemlerin operatör tarafından yapılması ilk bakışta daha kolay ve ucuz görünebilir. Ancak bu, otomatik hat kenarı ikmal ve taşımanın verimlilik, ürün kalitesi, ölçeklenebilirlik, sağlık ve emniyet açısından sağlayabileceği birçok iş avantajını gözden kaçıran, ileriyi göremeyen bir bakış açısıdır. Mevcut iş gücü krizinin üretim sektörü üzerindeki baskısı göz önüne alındığında, bu bakış açısı da gittikçe geçmişte kalmaktadır.

Değişimi benimseme: Esnek üretim sürecinin temel taşları

30 Ocak 2024, Salı Tüketicinin desteklenmesi, özelleştirmeye yönelik talepler, bilinçli sağlık tercihleri, veganlık, etik kaygılar ve sürdürülebilirlik gibi faktörlerin etkisiyle hızlı tüketim ürünleri pazarı köklü bir değişim yaşıyor. Önümüzdeki on yılda, önceki 50 yıla kıyasla daha fazla değişikliğin meydana geleceğini öngörüyoruz. Bu nedenle üretim ve tedarik zincirlerinin, yeni eğilimleri karşılayacak şekilde uyarlanması gerekiyor. Hızlı tüketim ürünleri fabrikalarının geleceği, muhtemelen ürünlerin ve birbiriyle bağlantılı sistemlerin otonom hareket ettiği daha küçük, daha akıllı tesislere doğru yol alacaktır.Bağımsız veya birbirine bağlı makinelerin, uygun malzeme ve paketlerin zamanında tedarik edilmesini sağlamak için her zamankinden daha esnek olması gerekiyor. Üretim daha çevik olmalı ve sıfır geri çağırma ile yüksek karışım, düşük hacim yaklaşımıyla perakendeye hazır ürünler üretmelidir. Buradaki esas soru, bu hedefe minimum maliyet ve hızlı yatırım getirisi ile nasıl ulaşılacağıdır.

2024 için otomasyonda neler bekleniyor? OMRON Europe'tan altı tahmin

13 Aralık 2023, Çarşamba Son birkaç yıldaki art arda gelen olumsuz gelişmeler, artan jeopolitik ve ekonomik risklerin yeni bir dönemini beraberinde getirdi. Bu durum, üreticileri iş modellerine dayanıklılık ve esneklik kazandırmaya, küresel tedarik zincirlerini ve ilişkilerini yeniden düşünmeye sevk ediyor. Aynı zamanda, ESG prensiplerini, operasyonel karar alma süreçlerine dahil etmeleri konusunda baskı artıyor. Yapay zeka, veri bilimi ve dijital ikizlerin yanı sıra algılama, izleme ve görsel denetim teknolojileri; üretim endüstrisinin bu yeni gerçeğe uyum sağlamasına yardımcı olacak otomasyon ve kontrol çözümlerini geliştirmek için temel unsurlar olacak. Bu bağlamda, 2024 ve sonrasında endüstriyel otomasyonu etkileyecek ve şekillendirecek altı temel trendi paylaşmak istiyorum.

Otomasyon Yardımıyla İş Gücü Eksikliğinin Üstesinden Gelmenin En İyi 4 Yolu

6 Eylül 2023, Çarşamba Otomasyon, manuel iş gücünün yerini almak yerine, manuel iş gücünü desteklemek amacıyla kullanılan bir yoldur.Üretimde iş gücü eksiklikleri, dünya genelinde endişe verici bir sorun haline gelmektedir. Finansal teşvikler ve hedeflenen iş gücü nitelikleri, bu soruna karşı önlemler olarak kullanılmış olsa da daha yenilikçi çözümlere ihtiyaç vardır. Birçok üretici, tekrarlayan faaliyetleri otomatikleştirmeyi tercih etmektedir ancak bu ne ölçüde mevcut iş gücünü desteklemektedir ya da bu, mevcut iş gücünün yerini tamamen mi almaktadır?2023 yılında Reuters, endişe verici bir trendi açıkladı: Şirketlerin %53'ü işe alım zorluklarıyla karşı karşıya ve bu rekor niteliğinde yüksek bir oran. Personel eksiklikleri ve yükselen enerji maliyetleri iklim nötr olma çabalarıyla bir araya gelerek yeni zorluklar yaratmaktadır. Sürdürülebilir üretim hedefi doğrultusunda, iş gücü eksiklikleriyle başa çıkmak ve mevcut yetenekleri geliştirmek için yenilikçi stratejiler oluşturmak, ilerlemenin anahtarıdır.Mevcut iş gücünü otomasyon ile desteklemenin ve iş gücü eksikliğini ele almanın en iyi dört yolunu gözden geçirelim:

OMRON Europe'tan 2023 için en iyi 5 otomasyon tahmini

1 Şubat 2023, Çarşamba Fırsatlarla dolu yeni bir yıla girmişken 2023 ve sonrasında endüstriyel otomasyonu etkileyecek ve şekillendirecek en önemli trendlerden bazılarını vurgulamak istiyorum. Üretim endüstrileri birçok zorlukla karşı karşıya kalmaya devam edecek ve bu zorlukları atlatmak, iş modellerine dayanıklılık ve esneklik kazandıracaktır. Şirketler aynı zamanda, toplumsal zorluklar nedeniyle karşılaştıkları sorunları çözmelerine yardımcı olmak için yeni teknolojileri (algılama, robot teknolojisi, 5G ve yapay zeka) benimsemelidir.

Fırtınadan sağ çıkanlar: toplumsal sorunları teknoloji fırsatlarına dönüştürerek ekonomik belirsizlikler arasında bir rota çizmek

6 Aralık 2022, Salı Bana sıkla sorulan sorulardan biri, bir endüstriyel otomasyon işletmesi olarak değişken ve gittikçe tahmin edilemez hale gelen küresel ekonomide kararlı bir büyüme sağlamak için stratejimizin ne olduğu. Tahmin edebileceğiniz gibi cevabım tek bir cümleden oluşmuyor ancak temelini tek bir kavramdan alıyor: SINIC. Çekirdek Yenilikten İhtiyaç Güdümlü Döngüsel Gelişime (Seed-Innovation to Need-Impetus Cyclic Evolution) anlamına gelen SINIC, OMRON'un kurucusu Dr. Kazuma Tateisi tarafından 1970 yılında geliştirilen bir teoridir. Bu felsefeye göre bilim, teknoloji ve toplum; birbirini karşılıklı olarak etkiledikleri döngüsel bir ilişki içindedir. Bilimsel gelişmeler toplumun gelişmesine yardımcı olurken toplumsal ihtiyaçlar ise teknolojik gelişimi teşvik eder. Başından beri bu felsefeyi uygulayan OMRON Europe, son on yıl boyunca günümüzün toplumsal ve ekonomik sorunlarına karşı katma değerli çözümler yaratmanın temellerini atmak için çalışmıştır.

KOBİ'ler İçin Otomasyona Yönelik Dört İpucu

25 Kasım 2022, Cuma Dünyanın dört bir yanındaki kurumsal liderler, peş peşe gelen zorluklarla yüzleşiyor. Enerji krizinden kaynaklanan maliyet artışlarına ek olarak tedarik zinciri sorunları, kalifiye çalışan eksikliği, sürdürülebilirlik gereksinimleri ve hızla ilerleyen dijitalleşme sorunları söz konusu. Özellikle, küçük ve orta ölçekli işletmelerin (KOBİ'ler) bu engellere hızla çözüm bulması gerekiyor. Otomasyon, bu çözümlerden biridir. Otomasyona kolaboratif robotlar ve AMR'nin (otonom mobil robotlar) yanı sıra sensörler, görsel denetim ve yapay zeka teknolojisi de dahildir. Şirketler bu tür teknolojilerin faydalarını bilse de araştırmalar, pek çok kişinin gerçek kullanım aşamasına yönelik şüpheleri olduğunu gösteriyor.Özellikle bu konuda deneyimi olmayan şirketler, robot kullanımının beraberinde maliyetlerin de yükseleceğinden korkuyor. Kolaboratif veya mobil robot satın almanın işletmeniz için faydalı olup olmayacağını merak ediyorsanız OMRON'un yeni yatırım getirisi hesaplayıcısı işinize yarayacaktır. Bu araç, size yatırım getirisi hakkında genel bir özet sunar ve robot yatırımlarının ne zaman kendi parasını karşılayacağını gösterir.

Otomotiv sektöründe dijitalleşme: Akıllı üretim için yedi ipucu

2 Kasım 2022, Çarşamba Büyümek ve krizlerin üstesinden gelmek istiyorsanız dijital olarak yeterli imkanlara sahip olmanız gerekir. Bu durum, oldukça önemli otomotiv sektörü için de geçerlidir. Müşteriler veya verimlilik söz konusu olduğunda dijital araçlara başvurmamak mümkün değildir. Capgemini tarafından gerçekleştirilen bir çalışmaya göre yapay zeka (AI) ve sürdürülebilirlik önemli etkenler ve odak konularıdır. Gartner uzmanları, açık kaynaklı iş birliği yaklaşımlarının, bütünsel ekosistemlerin ve teknoloji ortaklıklarının önemini vurguluyor. Peki, geleceğin üretiminde dijitalleşme ve intralojistik konusunda nelere dikkat etmeliyiz? Bu soruyu iki bölümde cevaplamak istiyoruz. Akıllı fabrikada dijitalleştirmeye ilişkin ipuçlarıyla başlıyoruz. Otomasyon uzmanı olarak OMRON, yıllarca daha gelişmiş bir dijitalleşmeye giden yollarında üreticilere ve tedarikçilere eşlik etmektedir.

Beka-Mak Makine, Omron Mobil ve Kolaboratif Robotları Makinalar ile Birlikte Çalıştırıyor

24 Ekim 2022, Pazartesi Beka-Mak, OMRON kolaboratif ve mobil robotlarını daire testere makinelerine entegre etti. Böylelikle kesintisiz üretim yapılması ve kesilen iş parçalarının istenilen ölçülerde paketlenmesi ile sevkiyat esnasındaki aksaklıların önüne geçilmesi hedefleniyor.1984 yılında aile şirketi olarak kurulan Beka-Mak, Türkiye’de testere makinası sektörünü global pazara açan lider firmadır. İlk ihracatını Almanya’ya 1991 senesinde gerçekleştiren Beka-Mak, bugün başta Avrupa, Rusya ve A.B.D olmak üzere dünyada 60 distribütör tarafından 78’e yakın ülkede temsil edilmektedir. Geniş ürün yelpazesiyle yüksek verimde çalışan daire ve şerit testere makinaları, Türkiye’nin önde gelen çelik üreticilerinin tercihi olmaktadır. Yenilikçi ve sürekli gelişim felsefesine sahip olan Beka-Mak, 2018 yılında kurulan tescilli Ar-Ge merkeziyle birlikte bugün 210 personel ile 22.500m² üretim alanında metal sektörüne katkıda bulunmaya devam ediyor.

Esnek Üretim Tanıtım Gezisi: Geleceğin fabrikası Avrupa yolculuğuna başladı

16 Haziran 2022, Perşembe Ya geleceğin fabrikasını görebilseydiniz, hissedebilseydiniz ve dokunabilseydiniz? Esnek, verimli ve sürdürülebilir üretimi gerçekleştirmek için ne gerekiyor? OMRON'un bu yıl Avrupa'yı dolaşan benzersiz Esnek Üretim Tanıtım Gezisinin arkasındaki fikir budur. Tanıtım gezisi, boyutları ve ölçekleri nedeniyle genellikle bir fabrika dışında görülmeyen insan-makine kolaboratif çözümlerinin özel gösterimlerini içeriyor.

Optimizasyondan otonomiye - OMRON'dan 2025 için en iyi beş üretim otomasyonu trendi

4 Ocak 2025, Cumartesi 2025'e adım atarken endüstriyel otomasyon dünyası çağ atlamaya yaklaşıyor. OMRON'un teknolojik gelişmeleri toplumsal değişimle ilişkilendiren SINIC Teorisine göre, artık Optimizasyon Toplumundan Otonom Topluma geçiş yapıyoruz. 1970 yılında OMRON'un kurucusu Kazuma Tateishi tarafından geliştirilen bu teori, yeniliğe kılavuzluk etmek için gelecekteki toplumsal ve teknolojik gelişmeleri öngörüyor. Optimizasyon aşamasında süreçlerin geliştirilmesi, verimliliğin artırılması ve operasyonların iyileştirilmesi için teknolojinin kullanılmasına odaklanılıyordu. Ancak Otonom Toplum, yepyeni bir çağ demek: Sistemlerin yalnızca verimli bir şekilde çalışmakla kalmayıp kendi kendini düzenleyen, kendi kendine öğrenen ve bağımsız karar verme yeteneğine sahip olduğu bir çağ.

Başarılı dijitalleşmenin ilk adımlarını atmak

12 Kasım 2024, Salı Dijital bir fabrika inşa etmek nihai bir hedef veya kendi başına bir neden değildir. Dijital fabrika, üretim işletmelerine pazardaki değişikliklere yanıt verme esnekliği sağlayan bir araçtır. Bu, inovasyon trendleri veya maliyet artışları gibi değişiklikler için yiyecek-içecek, kişisel bakım, ilaç veya otomotiv sektörlerinde kullanılabilir.

Açık standartlarla dijitalleştirmek: Gece rahat uyumanın anahtarı

2 Eylül 2024, Pazartesi Yaptığım tahminlere bağlı kalabilir miyiz? Teslim tarihine uyabilecek miyiz? Bundan emin olabilecek kadar bilgiye sahip miyim? QCDE (kalite, maliyet, teslimat süresi ve çevresel etki) açısından hedeflerimize göre ve rakiplerimizle karşılaştırıldığında fabrikanın durumu ne? Geceleri fabrika yöneticilerinin uykusunu kaçıran bu endişeler, dijitalleştirme yoluyla çözülebilir. Dijitalleştirilmiş bir üretim ortamında fabrika yöneticilerinin bilinmeyenler, riskler ve ortaya çıkabilecek durumlar hakkında endişelenmesine gerek yoktur. Dijitalleştirme, belirsizliği ortadan kaldırır ve performans odaklı optimizasyon sağlar. Fabrika yöneticilerinin kaliteyi iyileştirmelerine, maliyetleri düşürmelerine, teslim sürelerini kısaltmalarına ve çevresel etkileri azaltmalarına yardımcı olabilecek bilgileri sağlar. Dijitalleştirilmiş bir fabrikanın yöneticisi, gecenin bir yarısı endişe içinde uyanmaz ancak uyansa dahi cep telefonundan hızlıca her şeyin olması gerektiği gibi ilerlediğini kontrol edip kendini güvende hissedebilir. Ancak endişeyle geçen uykusuz gecelerden mışıl mışıl uyunan gecelere giden yol kolay değildir. Açık konuşmak gerekirse dijitalleştirme oldukça yorucu bir süreç olabilir. Proje liderleri nadiren temiz bir sayfada çalışma lüksüne sahiptir; çoğu zaman eski teknolojilerin birbirine yamalandığı bir kırkyama üzerinde çalışmaları gerekir. Daha önce hiç veri kaydetmemiş, henüz ortada veri haberleşme protokolleri dahi yokken üretilen makinelerden oluşan üretim hatlarını dijitalleştirmek için çaba gösterirler. Tüm bunlar bir araya geldiğinde ciddi bir OT ve IT entegrasyonu sorunu ortaya çıkar.

Robotic Trends 2024: Tam potansiyele ulaşmak için gereken basit ve esnek uygulama

3 Temmuz 2024, Çarşamba Yük taşıyıcıdan iş arkadaşına ve ekip oyuncusuna: Robotların rolü son yetmiş yıl içinde önemli ölçüde değişti. Yapay zeka daha fazla olasılık yaratıyor olsa da insanlar belirleyici faktör olmaya devam ediyor. Robotlar mı insanlar mı: Gelecekte üretimi kim şekillendirecek? 1954 yılında George Devol'un programlanabilir manipülatörün patentini almasından beri bu soru tartışmalara yol açmıştır. Devol'un Unimate adlı robotu tehlikeli görevleri güvenli bir şekilde yerine getirerek sektörde devrim yaratmış ve odak noktasının "insanlara karşı robotlar" değil, "robot + insan = verimlilik" olduğunu vurgulamıştır. 70 yılı aşkın bir sürede endüstri talepleri; esneklik, ölçeklenebilirlik, uyarlanabilirlik ve sürdürülebilirliğe öncelik verecek şekilde değişmiştir. Robotlar, insanların katma değerli faaliyetlere odaklanmaları için yükünü azaltan görevleri yerine getirmektedir.

2024 için otomasyonda neler bekleniyor? OMRON Europe'tan altı tahmin

13 Aralık 2023, Çarşamba Son birkaç yıldaki art arda gelen olumsuz gelişmeler, artan jeopolitik ve ekonomik risklerin yeni bir dönemini beraberinde getirdi. Bu durum, üreticileri iş modellerine dayanıklılık ve esneklik kazandırmaya, küresel tedarik zincirlerini ve ilişkilerini yeniden düşünmeye sevk ediyor. Aynı zamanda, ESG prensiplerini, operasyonel karar alma süreçlerine dahil etmeleri konusunda baskı artıyor. Yapay zeka, veri bilimi ve dijital ikizlerin yanı sıra algılama, izleme ve görsel denetim teknolojileri; üretim endüstrisinin bu yeni gerçeğe uyum sağlamasına yardımcı olacak otomasyon ve kontrol çözümlerini geliştirmek için temel unsurlar olacak. Bu bağlamda, 2024 ve sonrasında endüstriyel otomasyonu etkileyecek ve şekillendirecek altı temel trendi paylaşmak istiyorum.

EV geçişi kolaylaştırıldı: Otomotiv üretiminde üstesinden gelinecek en önemli üç zorluk

23 Kasım 2023, Perşembe Elektrikli araçlara geçiş, otomotiv üreticileri için zorlu bir süreçtir. Geleneksel olarak içten yanmalı motorlu araçlar üreten uzun ömürlü şirketler, şimdi tamamen yeni bir araç platformları dünyasına adım atmaktadır. Elektrikli araç üretim endüstrisinin karşılaştığı başlıca zorlukları inceleyelim ve ufuktaki en son yenilikçi çözümleri keşfedelim.

Zihinlerin buluşması: Endüstriyel otomasyonda IT/OT birleşimi

22 Eylül 2023, Cuma Gelecek odaklı üreticiler; esnek, verimli ve sürdürülebilir üretim ideallerine daha da yaklaşmak için dijital dönüşümü büyük bir ciddiyetle keşfetmektedir. Ne yazık ki dijitalleşmeye olan ilgi arttıkça OT (Operasyonel Teknoloji) ve IT (Bilgi Teknolojisi) dünyaları arasında büyük bir uçurum olduğu anlaşılıyor. Bu durumda, gelecekteki fabrikalar için hedeflenen bugünkü vizyonların, yarının gerçekliği haline gelmesi isteniyorsa bu farkın kapatılması gerekir. Ancak IT ve OT'nin neden bir araya getirilmesi gerektiğine ve bunun nasıl başarılabileceğine bakmadan önce temel bilgilere geri dönelim ve terminoloji hakkında bazı yanlış anlaşılmaları düzeltelim.

İş gücüne güç katma: OMRON'un Avrupa üretiminde beceri geliştirme yaklaşımı

6 Eylül 2023, Çarşamba OMRON'un yeni nesle güç kazandıran becerileri geliştirmeye olan sarsılmaz bağlılığını ele alırken sektörde dönüşüm dolu bir yolculuk başlıyor. Bu yolculuk, Dördüncü Sanayi Devrimi'nin (4IR) tüm potansiyelini ortaya çıkarırken diğer yandan cesurca Beşinci Sanayi Devrimi'ne (5IR) doğru ilerliyor.Akademik toplantı salonlarında, vizyoner iş liderlerinin yönetim kurulu odalarında ve ileri görüşlü siyasetçilerin ofislerinde hararetli tartışmalar yaşanıyor. Bütün bunların merkezinde Dördüncü Sanayi Devrimi, 4IR ya da diğer adıyla Endüstri 4.0'dan, yaşadığımız dünyayı değiştirecek olan Endüstri 5.0'a geçiş yer alıyor.Tarihsel olarak İlk Makine Çağı Sanayi Devrimi'yle, İkinci Makine Çağı da elektrikle başladı. Ardından elektronik ile Üçüncü, bir platform olarak internet ile de Dördüncü Makine Çağı'na girdik. Günümüzde ise insan ile makine arasındaki uyumlu iş birliğinin ve endüstrinin topluma katkılarının ön plana çıktığı Beşinci Makine Çağı'na doğru ilerliyoruz. Şimdi yalnızca uyum sağlamakla kalmayıp liderlik etme, öncülük yapma ve yeniliğin sınır tanımadığı bir gelecek yaratma zamanı. Dünya Ekonomik Forumu'nun kurucusu ve yönetim kurulu başkanı Klaus Schwab şöyle söylüyor: "Yaşama, çalışma ve birbirimiz ile ilişki kurma şeklimizi kökten değiştirecek bir teknolojik devrimin eşiğindeyiz. Ölçeği, kapsamı ve karmaşıklığı nedeniyle bu dönüşüm, insanlığın daha önce deneyimlediği her şeyden farklı olacak. Dünyamız dönüştürücü bir süreçten geçiyor. Akıllı teknoloji, makineler arası (M2M) haberleşme ve IoT entegrasyonuyla geleneksel endüstriyel uygulamaların otomasyonu sayesinde küresel üretim gelişiyor. Bu sinerji, daha yüksek düzeyde otomasyon ve sorunsuz haberleşmenin yanı sıra zorlukları otonom olarak analiz edip tanılayan akıllı makineleri destekliyor.Yapay zekanın yükselişi tartışmalara yol açarak toplumsal dokumuzdaki daha derin dönüşümlerin sinyalini veriyor. Bu dinamik ortamda ilerlerken inovasyonu benimsemeye ve geleceğimizi yeniden şekillendirmeye hazırız.

Kırmızı ışıklardan robotlara: OMRON, inovasyonla geçen 90 yılı kutluyor

6 Haziran 2023, Salı Bu yıl Kuruluş Gününde OMRON, teknolojinin sınırlarını zorladığı 90 yıla dönüp bakarken bir yandan da sürdürülebilirlik, dijitalleşme ve insan-makine iş birliğini temel alan otomasyon inovasyonu geleceğini sabırsızlıkla bekliyor.10 Mayıs Kuruluş Günümüz kutlu olsun… Her yıl 10 Mayıs günü, muhtemelen OMRON için takvimdeki en önemli gündür. Bu tarihte, dünyanın dört bir yanındaki 30.000 OMRON çalışanı, şirketin kurucusu olan Kazuma Tateishi'nin hayatını ve mirasını kutlar. Bunu Tateishi'nin daha iyi bir dünya yaratmak için teknolojiyi kullanma vizyonuna bağlılıklarını tazeleyerek ve genellikle kendi topluluklarındaki gönüllü projeler ve yardım projelerine katılmak aracılığıyla toplum yararına işler yaparak gerçekleştirirler. İnovasyonda Kilometre Taşları OMRON'un inovasyon yolculuğu, röntgen fotoğrafı için yüksek hassasiyetli bir zaman rölesi geliştirmesiyle 1933 yılında başladı. Bu da şirketin toplumsal ihtiyaçları ele alma konusundaki ilk katkısı oldu. 1960 yılında OMRON, dünyanın ilk temassız proximity switch'ini tanıtarak gelişmiş seri üretim yeteneklerinde çığır açtı. O günden bu yana OMRON; ilk otomatik trafik sinyali, insansız tren istasyonu sistemi, giyilebilir tansiyon kontrol cihazı, ultra yüksek hızlı bulanık lojik kontrolörü ve otomatik kanser hücresi tanılama ekipmanı gibi çığır açan teknolojileri tanıtmayı sürdürdü.

Yapay Zeka: Beni aptal sanmayın

8 Şubat 2023, Çarşamba On yıl önce kendi fabrikamızdaki makinelerin ne kadar akıllı olduğu konusunda bir hayli gururluydum. Şimdi, "akıllı" kavramına dair bugünkü algımı göz önünde bulundurduğumda aslında bir hayli aptal olduklarını fark ediyorum.Neden? Çünkü yapmak üzere tasarlandıkları şeyi yapmalarına rağmen, beklenmedik ya da sıra dışı bir durumla karşılaştıkları anda afallıyorlardı. Operatöre "Benim sorunum ne?" sorusunu sormak durumunda kalıyorlardı.Sorun giderme ve makinelerin onarılıp çalıştırılması, akıllı bireyleri gerektiriyordu. Son derece yetenekli operatörleri... Deneyimli yazılım ve donanım mühendislerini... Sorun şu ki son on yılda bu kişilerin bulunması gittikçe daha da zorlaştı. Sektöre giren yeni yeteneklerin sayısı, emeklilik yaşına ulaşan çalışanların sayısını dengeleyecek kadar yeterli değil. İşten ayrılan emekliler yılların tecrübesinin doruk noktası olan, iş başında emek vererek kazandıkları bilgileri yanlarında götürürler. Ayrılan her bir çalışanla birlikte işletmeler daha az verimli ve daha az yetenekli bir iş gücü olasılığıyla karşı karşıya kalır.

Net sıfıra giden yol: taktikler konusu

1 Şubat 2023, Çarşamba Üretimin net sıfıra ulaşabildiği bir gelecek için değer zinciri, otomasyonla dönüştürülmelidir.Haziran 2022'de New Scientist, dünyanın en büyük şirketlerinin üçte birinin net sıfır hedefi olduğunu, yani geçen yıldaki aynı döneme göre önemli ölçüde daha fazla şirket olduğunu bildirdi.İvmedeki artış olumlu bir gelişme olsa da makale, şirketlerin net sıfıra ulaşma planlarındaki ayrıntıların düzensiz olmasından da bahsediyor.Bu durum pek şaşırtıcı değil. Net sıfır stratejisi oluşturup uygulamak, özellikle de GHG emisyonlarının %80'i Kapsam 3'e giren şirketler için oldukça zordur. Bu emisyon, değer zincirinin girişinde ya da çıkışında oluşmaktadır. Bu, tedarik zinciri ve ürün dağıtım lojistiği hem uzun hem de karmaşık olan FMCG şirketleri için daha da büyük bir zorluktur.Bu işletmelerin çoğu, değer zincirinden karbonu çıkarması ve döngüsel bir değer zinciri elde etmesi gerektiğini biliyor. Bunu gerçekleştirmek için bir stratejileri de var. Bu strateji genel olarak, kaynak ve enerji kullanımının optimizasyonunu, yüksek emisyonlu ürünlerin ve süreçlerin değiştirilmesini ve atıkların ortadan kaldırılmasını kapsıyor.Buradaki asıl zorluk, niyeti eyleme dönüştürmektir. İşte tam da bu noktada otomasyon, çok kritik bir role sahiptir.Veri toplama ve analiz, net sıfıra başarılı bir geçişin anahtarıdır. Bu olmadan şirketler; başlangıç noktalarını, geliştirmeleri gereken yerleri, gelişip gelişmediklerini ve geliştilerse bunun ne kadar etkili olduğunu nasıl bilebilir? Sağlam veriler, taahhüdü değişim haline getirir, hem güvenilir hem de özgüvenli bir şekilde paydaşlarla iletişim kurmayı sağlar ve iklime yönelik çalışmaların gerçekleşmesine olanak tanır.

Otomasyon sayesinde enerji ve yakıt krizinin üstesinden gelme

7 Aralık 2022, Çarşamba Yükselen fiyatlara karşı koymak ve çevreyle ilgili hedefleri karşılamak adına endüstri şirketlerinin, tek kaynaklı otomasyon teknolojilerinin sürdürülebilirlik stratejilerine nasıl katkıda bulunabileceğini incelemesi gerekir.Yüksek enerji ve yakıt fiyatları, hem evlerimizde hem de endüstrilerimiz de zorluklara yol açıyor. Bu durum, mali planları ve cüzdanları olumsuz yönde etkilemekle kalmıyor, aynı zamanda aşırı yüksek fiyatlar nedeniyle bazı şirketler imalatı durdurmaya zorlanıyor. Make UK tarafından gerçekleştirilen bir ankette imalatçıların %42'si, elektrik faturalarının geçtiğimiz 12 ay içinde %100 zamlandığını belirtirken %32'si ise gaz fiyatlarının geçtiğimiz sene içinde %100 zamlandığını dile getiriyor. Endişe verici bir orana sahip %12'lik dilim ise yükselen enerji faturalarının doğrudan sonucu olarak işten çıkarmalara başladığını belirtti.Ukrayna'daki savaş, Covid-19 salgını ve gaz fiyatları krizin yalnızca birkaç nedeni; tüm bu nedenler bir araya gelerek tüm sektörleri ve enerji fiyatlarından tedarik zincirlerine kadar her alanı etkiliyor. Peki imalat şirketlerinin bu durumda ne yapması gerekiyor? Kapsamlı otomasyon stratejileri, daha yüksek esneklik ve enerji verimliliği açısından büyük bir önem taşıyor. Buna, sensör ve görsel denetim teknolojileriyle birlikte kullanılan yenilikçi robotların yanı sıra makine seviyesinde gerçek zamanlı yapay zeka (AI) da dahil. Ayrıca imalat tesislerinden alınan gerçek zamanlı veriler, anormallikleri tespit etme ve genel ekipman etkililiğini (OEE) artırma konusunda da yardımcı olabilir.

Elektrikli araç üretiminde otomatik denetim sistemlerinin kritik önemi

23 Mart 2023, Perşembe Emniyet, otomotiv sektöründeki tüm önceliklerin başında gelir ve elektrikli araç üretimi de bu durumda bir istisna değildir. Bununla birlikte emniyet, karmaşıklığa da yol açabilir ve günümüz araçlarında (özellikle EV'lerde) geleneksel örnekleme veya denetlemeye dayalı denetim yöntemleri yetersiz kalmaktadır.

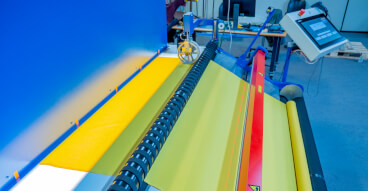

Vadain, makine görsel denetimiyle perde kumaşlarının denetimini otomatikleştirir

8 Nisan 2022, Cuma Hollanda'da özel perdelerin pazar lideri Vadain, kilometrelerce perde kumaşındaki hataları mümkün olduğunca erken tespit etmek için bir çözüme ihtiyaç duyuyordu. Sycade'de çalışan yazılım geliştiricileri, OMRON makine görsel denetim teknolojisi ve makine üreticisi Eisenkolb ile birlikte perde kumaşlarındaki hataları tespit etmek ve analiz etmek için otomatik bir çözüm geliştirdiler. Böylece, zaman alan manuel denetim süreci geçmişte kaldı.

Fabrika otomasyonu: Gıda ve içecek üretiminin geleceği hakkında dört ipucu

16 Temmuz 2020, Perşembe Koronavirüs salgını, türü ve boyutu fark etmeksizin tüm kuruluşları büyük sorunlarla baş başa bıraktı. Gıda sektöründe hizmet veren şirketler, önemli ölçüde azalan tüketim ve tedarik zincirinin sekteye uğraması gibi durumlardan muzdarip. Üstelik evde tüketim artarken ev dışı tüketim neredeyse durma noktasına geldi. Bu durumda üreticiler, iş stratejilerini ve üretim süreçlerini hem günümüze hem de ilerleyen zamanlara uygun hale getirmeyi nasıl başarabilir? Salgın, miadını doldurmuş süreçler ve prosedürler üzerinde tekrar düşünüp bunları yenilikçi robotik cihazlar, sensör teknolojisi ve bütüncül otomasyon stratejileri gibi kavramlarla geliştirmek için bir fırsat olarak değerlendirilebilir.

Endüstriyel şirketlerin markalarını korumak için üstesinden gelmesi gereken altı zorluk

19 Kasım 2019, Salı Her işletme, kendi markasının sektöründe en iyi bilinen ve en güvenilir marka olmasını sağlamaya çalışmalıdır. Ancak endüstriyel şirketler akıllı robotlar, yapay zeka ve görsel denetim sistemleri gibi yeni teknolojilere yatırım yaparken markalarını etkileyebilecek büyük zorlukları da göz önünde bulunduruyor mu?

Legacy of machine vision

16 Ekim 2019, Çarşamba Did you know that for more than 40 years, Omron has developed vision sensing technologies for factory automation, surveillance and transport systems, and more recently for facial recognition and image processing for mobile phones, and even driver monitoring for autonomous driving?

Farmasötik lojistiğinde ileri aşama özelleştirmeyi kolaylaştırma: küçük partileri yazdırma ve sipariş üzerine gönderme

16 Ekim 2019, Çarşamba Serileştirme mevzuatı, ileri aşamada basılan etiketlerin doğru olmasını ve uyumluluk için gerekli tüm verileri içermesini sağlamak için ilaç üreticilerine daha büyük talepler getiriyor. Farmasötik üretiminde ileri aşama özelleştirme, örneğin etiketlere veya önceden basılmış paketlere değişken veriler eklemeyi içerir. Bu, üreticinin her bir olası değişken için ayrı paketleme malzemeleri stoklamak zorunda kalmadan belirli pazarlar, müşteriler veya ürünler için ürün etiketlemeyi özelleştirmesine olanak tanır. Ayrıca, daha küçük parti boyutlarının esnek üretimi, otomatik ve hızlı geçişler için yeni gereklilikler getirir. İlaç üreticileri, düşük ve orta hacimli üretim için emniyet belirteçli, esnek bir çözümü nasıl uygulayabilir?

How to secure FMCG supply chains with traceability?

2 Ekim 2019, Çarşamba The traceability of food and drink products throughout the production and distribution process can be a complex issue. For example, alcoholic drink producers need systems that enable them to comply with local regulations regarding food traceability, as well as tax legislation.

Barcodes: keeping track of product quality

2 Ekim 2019, Çarşamba For many years, barcode technology has proved to be an economical and flexible identification technology. It has continued to develop and as a result, 1D and 2D codes (such as Datamatrix) are now used almost universally. Their versatility have made them a popular choice for streamlining many key supply chain processes, including production, logistics and item traceability.

Denetime hazır

12 Eylül 2019, Perşembe Kalite denetimi, tüm üretim ve paketleme hatları için büyük önem taşır. Kusurlu bir ürünün müşterilere ulaştırılmadan önce fark edilebilmesi yüksek maliyetli ürün geri çağırma süreçlerini, üretim kaybını ve olası yasal maliyetleri önleyerek zaman ve maliyet tasarrufu sağlar.

Teknoloji hedefinin ötesinde: Endüstriyel otomasyon, operasyonel mükemmellikle buluştuğunda ne olur?

30 Kasım 2024, Cumartesi Son birkaç yılda teknolojide hızlı gelişmeler yaşandı ve yapay zekanın yükselişi önemli bir trend olarak öne çıktı. Birleşik Krallık, ABD ve Kanada'da üreticiler arasında yapılan bir ankette, katılımcıların %70'i operasyonlarına bir tür yapay zeka uyguladıklarını belirtti. Özellikle üretim sektörleri otomasyon ile büyük avantajlar elde edebileceğinden yeni teknolojileri benimsemeye yönelik güçlü bir istek söz konusudur.

Başarılı dijitalleşmenin ilk adımlarını atmak

12 Kasım 2024, Salı Dijital bir fabrika inşa etmek nihai bir hedef veya kendi başına bir neden değildir. Dijital fabrika, üretim işletmelerine pazardaki değişikliklere yanıt verme esnekliği sağlayan bir araçtır. Bu, inovasyon trendleri veya maliyet artışları gibi değişiklikler için yiyecek-içecek, kişisel bakım, ilaç veya otomotiv sektörlerinde kullanılabilir.

Verimlilik tıkanıklığından kaçınmak: Şirketler robot planlarını neden ertelememelidir?

24 Eylül 2024, Salı Yenilikçi teknolojilere yapılan yatırımları geciktirmek birçok riskle ilişkilidir. Bu konuda hâlâ tereddüt eden şirketler kendilerine üç soru sormalıdır.Avrupa ekonomisi büyüme, istikrar ve rekabet gücünü etkileyen çeşitli güçlüklerle karşı karşıya. Örneğin Avrupa, dünyadaki en yaşlı nüfuslardan birine sahip. Yaşlanan iş gücü, sosyal güvenlik sistemleri üzerindeki yükü artırıyor ve iş gücü tedarikini azaltarak ekonomik büyümeyi potansiyel olarak yavaşlatıyor. Ayrıca, AB'nin Yeşil Mutabakat'a ve 2050 yılına kadar karbon nötrlüğünün sağlanmasına bağlılığı çeşitli sektörlerde önemli yatırımlar ve yapısal değişiklikler yapılmasını gerektiriyor. Bunun yanı sıra finansal endişeler nedeniyle yatırım yapma isteksizliği de söz konusu. McKinsey Global Institute (MGI) tarafından kısa süre önce yapılan bir araştırma, 1 milyar dolardan fazla gelir elde eden büyük Avrupalı firmaların ABD'deki benzer firmaların gerisinde kaldığını ortaya çıkardı. Yılda toplam 400 milyar dolar daha az yatırım yapıyor ve üçte bir oranında daha yavaş büyüyorlar.Bu yatırım hevessizliği; rekabet gücü, sürdürülebilirlik ve itibar açısından dezavantajlar, yetersiz verimlilik ve yeni nitelikli çalışanların ilgisini çekmede azalan başarı gibi kısa ve uzun vadeli etkileri olan çeşitli sorunlara yol açabiliyor. Yenilikçi robot teknolojisi bu tür gelişmelerle mücadele edebiliyor olsa da iyi düşünülmüş bir finansman kapasitesi de gerektiriyor. Bu nedenle, şu anda yatırımlarını kısıtlayan şirketler, bunun uzun vadede kısa vadeli tasarruflardan daha fazla olumsuz sonucu olup olmayacağını acilen kendilerine sormalıdır. Aşağıdaki üç soru, bu hususların odak noktası olmalıdır:

Açık standartlarla dijitalleştirmek: Gece rahat uyumanın anahtarı

2 Eylül 2024, Pazartesi Yaptığım tahminlere bağlı kalabilir miyiz? Teslim tarihine uyabilecek miyiz? Bundan emin olabilecek kadar bilgiye sahip miyim? QCDE (kalite, maliyet, teslimat süresi ve çevresel etki) açısından hedeflerimize göre ve rakiplerimizle karşılaştırıldığında fabrikanın durumu ne? Geceleri fabrika yöneticilerinin uykusunu kaçıran bu endişeler, dijitalleştirme yoluyla çözülebilir. Dijitalleştirilmiş bir üretim ortamında fabrika yöneticilerinin bilinmeyenler, riskler ve ortaya çıkabilecek durumlar hakkında endişelenmesine gerek yoktur. Dijitalleştirme, belirsizliği ortadan kaldırır ve performans odaklı optimizasyon sağlar. Fabrika yöneticilerinin kaliteyi iyileştirmelerine, maliyetleri düşürmelerine, teslim sürelerini kısaltmalarına ve çevresel etkileri azaltmalarına yardımcı olabilecek bilgileri sağlar. Dijitalleştirilmiş bir fabrikanın yöneticisi, gecenin bir yarısı endişe içinde uyanmaz ancak uyansa dahi cep telefonundan hızlıca her şeyin olması gerektiği gibi ilerlediğini kontrol edip kendini güvende hissedebilir. Ancak endişeyle geçen uykusuz gecelerden mışıl mışıl uyunan gecelere giden yol kolay değildir. Açık konuşmak gerekirse dijitalleştirme oldukça yorucu bir süreç olabilir. Proje liderleri nadiren temiz bir sayfada çalışma lüksüne sahiptir; çoğu zaman eski teknolojilerin birbirine yamalandığı bir kırkyama üzerinde çalışmaları gerekir. Daha önce hiç veri kaydetmemiş, henüz ortada veri haberleşme protokolleri dahi yokken üretilen makinelerden oluşan üretim hatlarını dijitalleştirmek için çaba gösterirler. Tüm bunlar bir araya geldiğinde ciddi bir OT ve IT entegrasyonu sorunu ortaya çıkar.

2024 için otomasyonda neler bekleniyor? OMRON Europe'tan altı tahmin

13 Aralık 2023, Çarşamba Son birkaç yıldaki art arda gelen olumsuz gelişmeler, artan jeopolitik ve ekonomik risklerin yeni bir dönemini beraberinde getirdi. Bu durum, üreticileri iş modellerine dayanıklılık ve esneklik kazandırmaya, küresel tedarik zincirlerini ve ilişkilerini yeniden düşünmeye sevk ediyor. Aynı zamanda, ESG prensiplerini, operasyonel karar alma süreçlerine dahil etmeleri konusunda baskı artıyor. Yapay zeka, veri bilimi ve dijital ikizlerin yanı sıra algılama, izleme ve görsel denetim teknolojileri; üretim endüstrisinin bu yeni gerçeğe uyum sağlamasına yardımcı olacak otomasyon ve kontrol çözümlerini geliştirmek için temel unsurlar olacak. Bu bağlamda, 2024 ve sonrasında endüstriyel otomasyonu etkileyecek ve şekillendirecek altı temel trendi paylaşmak istiyorum.

Zihinlerin buluşması: Endüstriyel otomasyonda IT/OT birleşimi

22 Eylül 2023, Cuma Gelecek odaklı üreticiler; esnek, verimli ve sürdürülebilir üretim ideallerine daha da yaklaşmak için dijital dönüşümü büyük bir ciddiyetle keşfetmektedir. Ne yazık ki dijitalleşmeye olan ilgi arttıkça OT (Operasyonel Teknoloji) ve IT (Bilgi Teknolojisi) dünyaları arasında büyük bir uçurum olduğu anlaşılıyor. Bu durumda, gelecekteki fabrikalar için hedeflenen bugünkü vizyonların, yarının gerçekliği haline gelmesi isteniyorsa bu farkın kapatılması gerekir. Ancak IT ve OT'nin neden bir araya getirilmesi gerektiğine ve bunun nasıl başarılabileceğine bakmadan önce temel bilgilere geri dönelim ve terminoloji hakkında bazı yanlış anlaşılmaları düzeltelim.

İş gücüne güç katma: OMRON'un Avrupa üretiminde beceri geliştirme yaklaşımı

6 Eylül 2023, Çarşamba OMRON'un yeni nesle güç kazandıran becerileri geliştirmeye olan sarsılmaz bağlılığını ele alırken sektörde dönüşüm dolu bir yolculuk başlıyor. Bu yolculuk, Dördüncü Sanayi Devrimi'nin (4IR) tüm potansiyelini ortaya çıkarırken diğer yandan cesurca Beşinci Sanayi Devrimi'ne (5IR) doğru ilerliyor.Akademik toplantı salonlarında, vizyoner iş liderlerinin yönetim kurulu odalarında ve ileri görüşlü siyasetçilerin ofislerinde hararetli tartışmalar yaşanıyor. Bütün bunların merkezinde Dördüncü Sanayi Devrimi, 4IR ya da diğer adıyla Endüstri 4.0'dan, yaşadığımız dünyayı değiştirecek olan Endüstri 5.0'a geçiş yer alıyor.Tarihsel olarak İlk Makine Çağı Sanayi Devrimi'yle, İkinci Makine Çağı da elektrikle başladı. Ardından elektronik ile Üçüncü, bir platform olarak internet ile de Dördüncü Makine Çağı'na girdik. Günümüzde ise insan ile makine arasındaki uyumlu iş birliğinin ve endüstrinin topluma katkılarının ön plana çıktığı Beşinci Makine Çağı'na doğru ilerliyoruz. Şimdi yalnızca uyum sağlamakla kalmayıp liderlik etme, öncülük yapma ve yeniliğin sınır tanımadığı bir gelecek yaratma zamanı. Dünya Ekonomik Forumu'nun kurucusu ve yönetim kurulu başkanı Klaus Schwab şöyle söylüyor: "Yaşama, çalışma ve birbirimiz ile ilişki kurma şeklimizi kökten değiştirecek bir teknolojik devrimin eşiğindeyiz. Ölçeği, kapsamı ve karmaşıklığı nedeniyle bu dönüşüm, insanlığın daha önce deneyimlediği her şeyden farklı olacak. Dünyamız dönüştürücü bir süreçten geçiyor. Akıllı teknoloji, makineler arası (M2M) haberleşme ve IoT entegrasyonuyla geleneksel endüstriyel uygulamaların otomasyonu sayesinde küresel üretim gelişiyor. Bu sinerji, daha yüksek düzeyde otomasyon ve sorunsuz haberleşmenin yanı sıra zorlukları otonom olarak analiz edip tanılayan akıllı makineleri destekliyor.Yapay zekanın yükselişi tartışmalara yol açarak toplumsal dokumuzdaki daha derin dönüşümlerin sinyalini veriyor. Bu dinamik ortamda ilerlerken inovasyonu benimsemeye ve geleceğimizi yeniden şekillendirmeye hazırız.

Kırmızı ışıklardan robotlara: OMRON, inovasyonla geçen 90 yılı kutluyor

6 Haziran 2023, Salı Bu yıl Kuruluş Gününde OMRON, teknolojinin sınırlarını zorladığı 90 yıla dönüp bakarken bir yandan da sürdürülebilirlik, dijitalleşme ve insan-makine iş birliğini temel alan otomasyon inovasyonu geleceğini sabırsızlıkla bekliyor.10 Mayıs Kuruluş Günümüz kutlu olsun… Her yıl 10 Mayıs günü, muhtemelen OMRON için takvimdeki en önemli gündür. Bu tarihte, dünyanın dört bir yanındaki 30.000 OMRON çalışanı, şirketin kurucusu olan Kazuma Tateishi'nin hayatını ve mirasını kutlar. Bunu Tateishi'nin daha iyi bir dünya yaratmak için teknolojiyi kullanma vizyonuna bağlılıklarını tazeleyerek ve genellikle kendi topluluklarındaki gönüllü projeler ve yardım projelerine katılmak aracılığıyla toplum yararına işler yaparak gerçekleştirirler. İnovasyonda Kilometre Taşları OMRON'un inovasyon yolculuğu, röntgen fotoğrafı için yüksek hassasiyetli bir zaman rölesi geliştirmesiyle 1933 yılında başladı. Bu da şirketin toplumsal ihtiyaçları ele alma konusundaki ilk katkısı oldu. 1960 yılında OMRON, dünyanın ilk temassız proximity switch'ini tanıtarak gelişmiş seri üretim yeteneklerinde çığır açtı. O günden bu yana OMRON; ilk otomatik trafik sinyali, insansız tren istasyonu sistemi, giyilebilir tansiyon kontrol cihazı, ultra yüksek hızlı bulanık lojik kontrolörü ve otomatik kanser hücresi tanılama ekipmanı gibi çığır açan teknolojileri tanıtmayı sürdürdü.

Satın Alma mı Kiralama mı? Yeni cobotunuzu finanse etmenin yolu

26 Nisan 2023, Çarşamba Otomasyon projelerini finanse ederken KOBİ'lerin düşünmesi gereken bir noktaBeceri eksiklikleri, dijitalleşme, sürdürülebilirlik ve enerji tasarrufu planları birçok şirkette otomasyon projelerini hızlandırmaktadır. Otomasyona kayan manuel süreçler belirlendikten sonra genelde akıllara şu soru gelir: Tüm bunlar ne kadara mal olur?Kiralama veya hizmet olarak robot gibi seçenekleri göz önünde bulundurmak mantıklı olabilir. Küçük ve orta ölçekli işletmelere (KOBİ'ler) özellikle otomasyonun finansal yönleri hakkında daha iyi bir genel bakış sağlayan araçlardan biri de OMRON yatırım getirisi hesaplayıcısıdır. Bir cobot veya AMR satın almayı düşünen herkes bu aracı kullanarak yatırım getirisini görebilir.

Cobot entegrasyonunu hızlandırma

8 Şubat 2023, Çarşamba İyi planlama ve güçlü iş ortakları, KOBİ'lerin otomasyondaki engellerin üstesinden gelmelerine yardımcı olur.Cobotlar olarak da bilinen kolaboratif robotlar, zaman alan ve kaynak kullanımı gerektiren görevleri otomatikleştirmeyi mümkün kıldıkları için fazlasıyla rağbet görüyor. Küresel kolaboratif robot pazarının şu anda yaklaşık 1,2 milyar dolar olduğu tahmin ediliyor. Cobotların satış hacmi 2021'de toplam 32.300 birime ulaştı. Özellikle şirketlerin uygun çalışanları bulması ve şirket bünyesinde tutması gittikçe zorlaşırken bu teknolojiler birçok yerde gördüğü değeri hak ediyor. Değerden söz etmişken, bazılarının aklına şu soru gelebilir: Cobotlar son derece pahalıdır, değil mi? Böyle bir yatırım ne zaman karşılığını veriyor?Otomasyon uzmanı OMRON, özellikle küçük ve orta ölçekli şirketler için bu tür kaygıları hafifletmek istiyor: Akıllı ve entegre robot çözümlerinin yanı sıra cobotlar ve mobil robotlar elverişli ve uygun maliyetlidir. OMRON yatırım getirisi hesaplayıcısı, yatırım getirisi hakkında fikir edinmek isteyenlere hızlı ve kolay bir genel bakış sağlar.Cobotlar ve otonom mobil robotlar (AMR), hem KOBİ'ler hem de büyük ölçekli işletmeler için uygundur. Bu robotlar; taşıma, paletleme, makineleri yükleme ve boşaltma, montaj, boyama veya kaynak gibi görevleri yerine getirir. Ayrıca, hızlı ve esnek bir şekilde yenilenebilir ve uzman olmayan kişiler tarafından programlanabilirler. Malzeme ikmali, cobotlar aracılığıyla makine ve süreç yükleme ve AMR'ler ile kolaylaştırılabilir. Ancak bu tür projeleri başarıyla gerçekleştirmek ve robot entegrasyonunu hızlandırmak için teknik bilgiler ve konuya aşina olan iş ortakları gereklidir. Hepsinden önemlisi, çalışanların hep birlikte değişimin bir parçası olmaları için projenin başından itibaren bilgilendirilmeleri ve sürece dahil olmaları gerekir.Aşağıda, cobotları entegre ederken şirketlerin akıllarında tutması gereken bazı ipuçları verilmiştir:

Yapay Zeka: Beni aptal sanmayın

8 Şubat 2023, Çarşamba On yıl önce kendi fabrikamızdaki makinelerin ne kadar akıllı olduğu konusunda bir hayli gururluydum. Şimdi, "akıllı" kavramına dair bugünkü algımı göz önünde bulundurduğumda aslında bir hayli aptal olduklarını fark ediyorum.Neden? Çünkü yapmak üzere tasarlandıkları şeyi yapmalarına rağmen, beklenmedik ya da sıra dışı bir durumla karşılaştıkları anda afallıyorlardı. Operatöre "Benim sorunum ne?" sorusunu sormak durumunda kalıyorlardı.Sorun giderme ve makinelerin onarılıp çalıştırılması, akıllı bireyleri gerektiriyordu. Son derece yetenekli operatörleri... Deneyimli yazılım ve donanım mühendislerini... Sorun şu ki son on yılda bu kişilerin bulunması gittikçe daha da zorlaştı. Sektöre giren yeni yeteneklerin sayısı, emeklilik yaşına ulaşan çalışanların sayısını dengeleyecek kadar yeterli değil. İşten ayrılan emekliler yılların tecrübesinin doruk noktası olan, iş başında emek vererek kazandıkları bilgileri yanlarında götürürler. Ayrılan her bir çalışanla birlikte işletmeler daha az verimli ve daha az yetenekli bir iş gücü olasılığıyla karşı karşıya kalır.

Gelecek intralojistiğe mi yöneliyor? Daha fazla verimlilik için ipuçları

15 Kasım 2022, Salı Bazen büyük resme o kadar çok odaklanırız ki akıllı üretimi simgeleyen küçük ve çok önemli olan süreçleri unuturuz. Buna örnek olarak intralojistiği, yani bir şirketin tesislerinde veya üretim salonunda gerçekleşen malzeme ve ürün akışlarını verebiliriz. Kısa bir süre önce yapılan bir çalışma, ankete katılan şirketlerin yüzde 80'inden fazlasının, kalifiye çalışan eksikliği veya büyüme planları gibi zorlukların üstesinden gelmek için intralojistikte yapay zeka ve otomasyon kullanımının artmasını gerekli bulduğunu ortaya koydu.Pazar ve müşteri gereksinimlerini karşılamak, verimliliği artırmak ve daha sürdürülebilir olmak isteyen otomotiv şirketleri yeni fikirler üretmelidir. Enerji maliyetleri, gaz krizi ve yükselen enflasyon bu görevi daha da zorlaştırmaktadır. Yenilikçi otomasyon, dijitalleşme ve akıllı intralojistik yaklaşımlarını bir araya getiren akıllı fabrika konseptleri, değerli destekler sağlayabilir. Bazıları bu bağlamda Endüstri 4.0'dan bahsederken bazıları "geleceğin fabrikası", bazıları ise Endüstriyel Nesnelerin İnterneti'ni (IIoT) tercih ediyor. Ancak hangi yaklaşımı seçerseniz seçin, en önemlisi şimdi harekete geçmek ve güvenilir iş ortaklarıyla çalışmaktır. İntralojistik, değişimi hızlı bir şekilde başlatmak için iyi bir başlangıç noktasıdır çünkü acilen harekete geçilmesi gerekiyor. Şu anda birçok şirket, kalifiye çalışan eksikliği nedeniyle ciddi ölçüde kısıtlanmıştır. Mobil robotlar gibi modern teknolojiler çözüm sağlayabilir.

PPWR: Zincirler arası iş birliği, izlenebilirlik ve akıllı paketleme neden kritiktir?

24 Eylül 2024, Salı Eurostat rakamlarına göre 2021 yılında AB'de yaşayan insanlar kişi başına 188,7 kg ambalaj atığı oluşturdu ve bu sayı, 2011'e kıyasla yaklaşık 32 kg fazla. Bu süre içinde plastik ambalaj atık miktarı %27 arttı. Geri dönüşüm oranları da artmış olmasına rağmen plastik ambalajların büyük bir kısmı hala geri dönüştürülmemektedir; en son istatistikler, Avrupa'da plastikler için %50 geri dönüşüm oranına yalnızca bir avuç ülkenin ulaşabildiğini gösteriyor. Mevcut yasal çerçevenin ambalaj atıklarının azaltılmasında iyileşme sağlamadığını kabul eden Komisyon, 2022 yılında 2018 tarihli Ambalaj ve Ambalaj Atıkları Mevzuatı (PPWR) direktifinde bir revizyon yapılmasını önermiştir.Revize edilen PPWR'nin yıl sonu itibarıyla yürürlüğe girmesi ve ambalajların tasarlanma, tüketilme ve bertaraf edilme süreçlerini kökten değiştirmesi bekleniyor. Güncellenen mevzuatın kapsamı geniş olsa da temel amaç, üretilen ambalaj atığı miktarını azaltmak ve ambalajların geri dönüştürülebilirliğini artırmaktır.

EV üreticilerinin sürdürülebilir bir geleceğe ulaşma yolculuğunda karşılaştığı en büyük 4 zorluk

17 Haziran 2024, Pazartesi Elektrikli araçlar (EV'ler) son yıllarda spesifik bir pazar olmaktan çıkıp sektörde büyük bir güç haline geldi. IEA Küresel EV Görünümü 2024'e göre, 2023 yılı itibarıyla satılan yaklaşık her beş araçtan biri elektrikli araçtır ve elektrikli araç satışları 3,5 milyon birim artmıştır, yani önceki yıla göre %35'lik bir artış elde edilmiştir. Bu artışın devam etmesi bekleniyor ve yükselen pazarlardaki satışların 2024 yılında, 2023'e göre %40'lık bir artışla 1 milyon birimi aşacağını belirten tahminler yapılıyor. Dünya çapındaki hükümetler, CO2 emisyonlarını azaltmak için baskı yapıyor ve bu da elektrikli araçlara geçişi hızlandırıyor.Peki bu, otomotiv üreticileri için ne anlama geliyor? Birincisi, ağırlıklı olarak elektrikli filolar tasarlamaya ve üretmeye odaklanmaları gerektiği anlamına geliyor, birçok üretici halihazırda bu yönde harekete geçmiş durumda. İkinci olarak ise yeni üretim hatları oluşturmak ve yeni üretim süreçlerinde ustalaşmak gerekiyor, bu da epey zorlayıcı olabiliyor.Güvenilir bir otomasyon iş ortağı burada devreye giriyor. Otomasyon konusunda bir uzmanla iş ortaklığı kurmak, sektör genelindeki bu geçişin karmaşıklıklarını yönetmeye yardımcı olabilir. Geniş bir teknoloji portföyü, küresel destek ve otomotiv alanındaki engin uzmanlık bilgileriyle OMRON, elektrikli araçlara geçiş yolculuklarında üreticilere rehberlik etmeye hazırdır.Bu blog yazısında, EV (elektrikli araç) üretim sektöründeki en büyük zorluklar ve OMRON ile iş ortaklığı kurmanın bu zorluklara nasıl etkili çözümler sağlayabileceği açıklanacaktır:

Değişimin aracısı olarak akıllı otomasyon

31 Mayıs 2024, Cuma Üretim sektörü, küresel sera gazı emisyonlarının yaklaşık dörtte birinden sorumludur¹ ve bu da onu, karbon emisyonlarına en fazla katkıda bulunan ikinci sektör olan taşımacılıkla aynı sıraya koymaktadır. Bu durum üretim sektörünün karbon ayak izini azaltmanın, iklim değişikliği üzerindeki etkimizi azaltmada önemli bir rol oynayacağı anlamına gelmektedir.Üretim sektörünün artık bir sorun kaynağı olmak yerine çözüm kaynaklarından biri olmanın yanı sıra, iklim değişikliğini ele alıp, süreçteki değişim aracısı olarak otomasyonu kullanıp potansiyelini ortaya çıkarmaya başlamasının zamanı geldi.Bu; kurucumuzun, bir işletme olarak faaliyet gösterdiğimiz toplum yararına işler yama sorumluluğumuza olan inancını yansıtmaktadır. 90 yıldan uzun bir süre önce OMRON, kurucusu Kazuma Tateishi'nin daha iyi bir dünya için teknolojiden faydalanma vizyonuyla ortaya çıktı.Tateishi'nin "yaşamları iyileştirme ve daha iyi bir topluma katkıda bulunma" konusundaki inancı, bir toplum olarak karşılaştığımız iklim zorlukları göz önüne alındığında şu ana kadar hiç olmadığı kadar büyük bir öneme sahiptir. Peki, üretim nasıl olumlu bir fark yaratabilir?

Bozulmadıysa bile kurcalamanız gerekebilir

4 Nisan 2024, Perşembe Akıllı enerji yönetimi ile FMCG üretimini daha sürdürülebilir hale getirme

Kadınların gücünü gösterin! Otomasyon alanında heyecan verici kariyer fırsatlarını keşfedin

1 Mart 2024, Cuma OMRON'da çalışan deneyimli otomasyon uzmanları Maryam Dolatabadi ve Asunción Pastrana Costa, gençten yetişkine tüm kadınlara sesleniyorlar: "Cesur olun, sektörde size hemen ihtiyacımız var!"

Endüstriyel otomasyon ve robotlar: Hala erkek egemen bir alan mı?

7 Şubat 2024, Çarşamba Günümüzde otomasyon alanında kadın olmak nasıl bir şey? OMRON Europe'tan üç kadın, endüstriyel otomasyon dünyasındaki deneyimlerinden, karşılaştıkları zorluklardan ve başarılı olmalarına yardımcı olan destek ve araçlardan bahsediyor.Wendy Tonks yaklaşık 20 yıl önce Birleşik Krallık'ta mühendislik kariyerine ilk başladığında, koymak zorunda kaldığı ilk kural çaycı kadın olmadığıydı.

2024 için otomasyonda neler bekleniyor? OMRON Europe'tan altı tahmin

13 Aralık 2023, Çarşamba Son birkaç yıldaki art arda gelen olumsuz gelişmeler, artan jeopolitik ve ekonomik risklerin yeni bir dönemini beraberinde getirdi. Bu durum, üreticileri iş modellerine dayanıklılık ve esneklik kazandırmaya, küresel tedarik zincirlerini ve ilişkilerini yeniden düşünmeye sevk ediyor. Aynı zamanda, ESG prensiplerini, operasyonel karar alma süreçlerine dahil etmeleri konusunda baskı artıyor. Yapay zeka, veri bilimi ve dijital ikizlerin yanı sıra algılama, izleme ve görsel denetim teknolojileri; üretim endüstrisinin bu yeni gerçeğe uyum sağlamasına yardımcı olacak otomasyon ve kontrol çözümlerini geliştirmek için temel unsurlar olacak. Bu bağlamda, 2024 ve sonrasında endüstriyel otomasyonu etkileyecek ve şekillendirecek altı temel trendi paylaşmak istiyorum.

İş gücüne güç katma: OMRON'un Avrupa üretiminde beceri geliştirme yaklaşımı